MC-CRAFT Videos

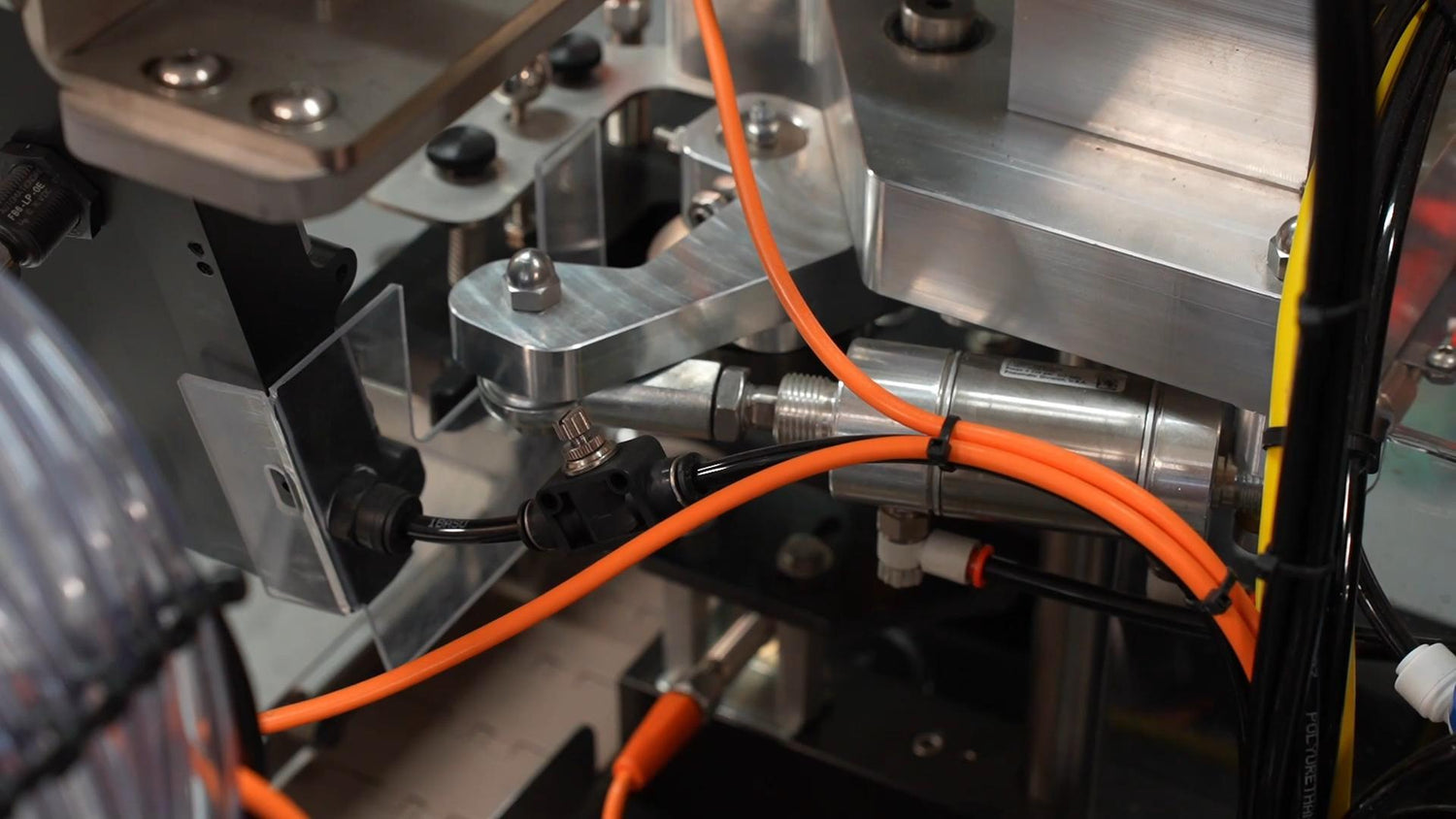

Cleaning and Lubricating a Cylinder

Keep your cylinders from going bad, learn how to clean and lubricate them

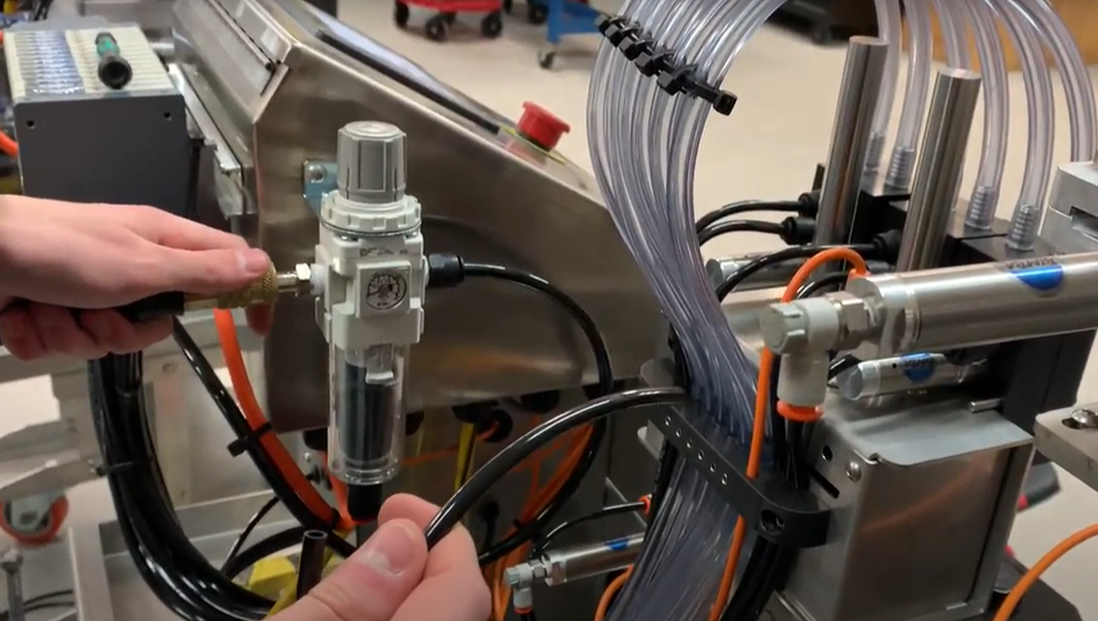

How to Drain your Air Compressor

Prevents air cylinders speed from changing and helps prevent flow controls becoming inoperable

Setting Cylinder Speeds

Learn how to change the speeds of the air cylinders on your machine

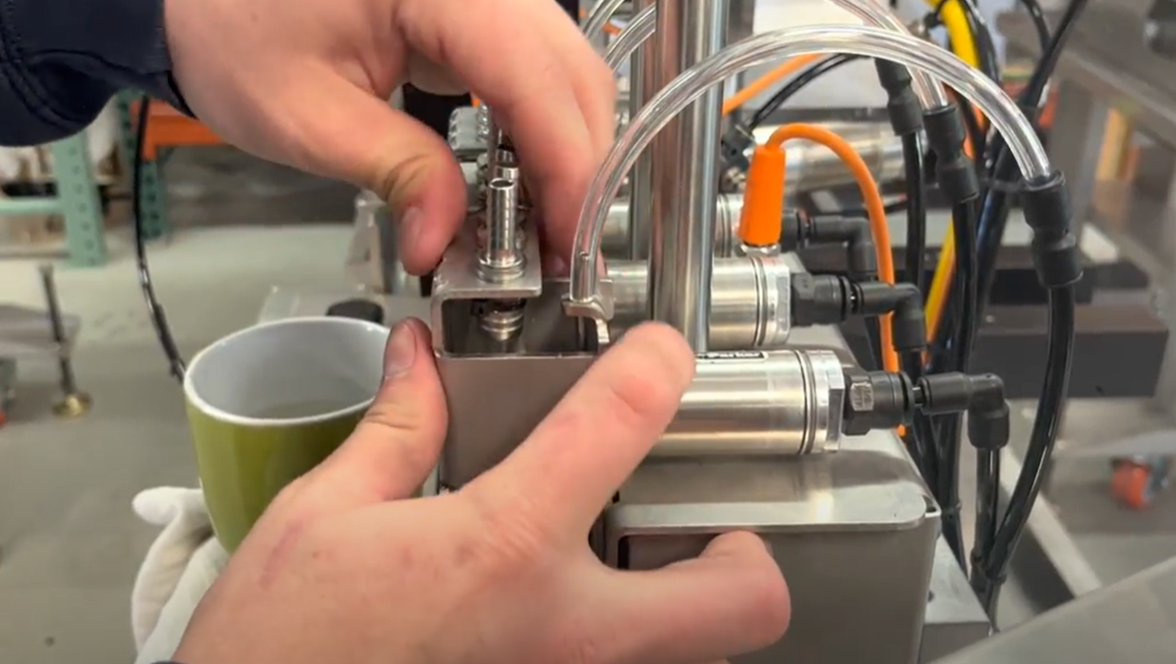

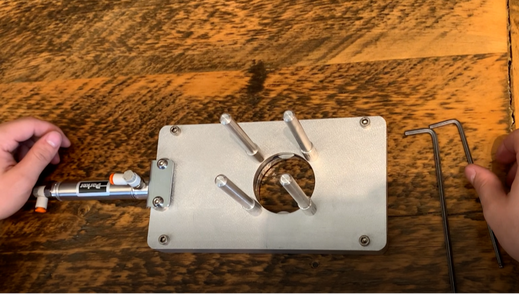

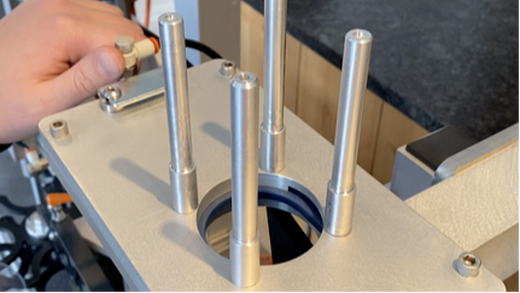

Leak Testing a Cylinder

Can diagnose a bad air cylinder. Bad air cylinders will extend and or retract inconsistently.

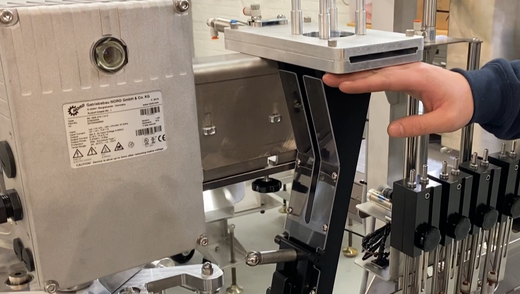

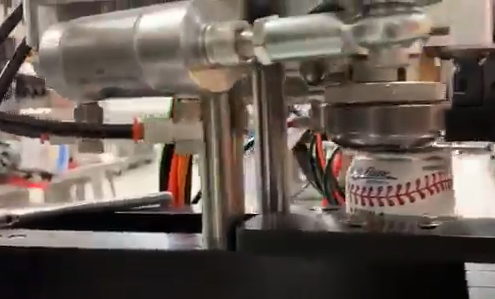

Setting Operation Heights

Can fix seam heights and even the seamer motor stalling during a seam. Also prevents premature chuck failure

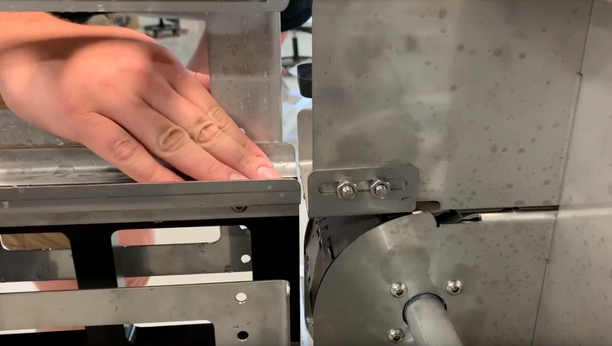

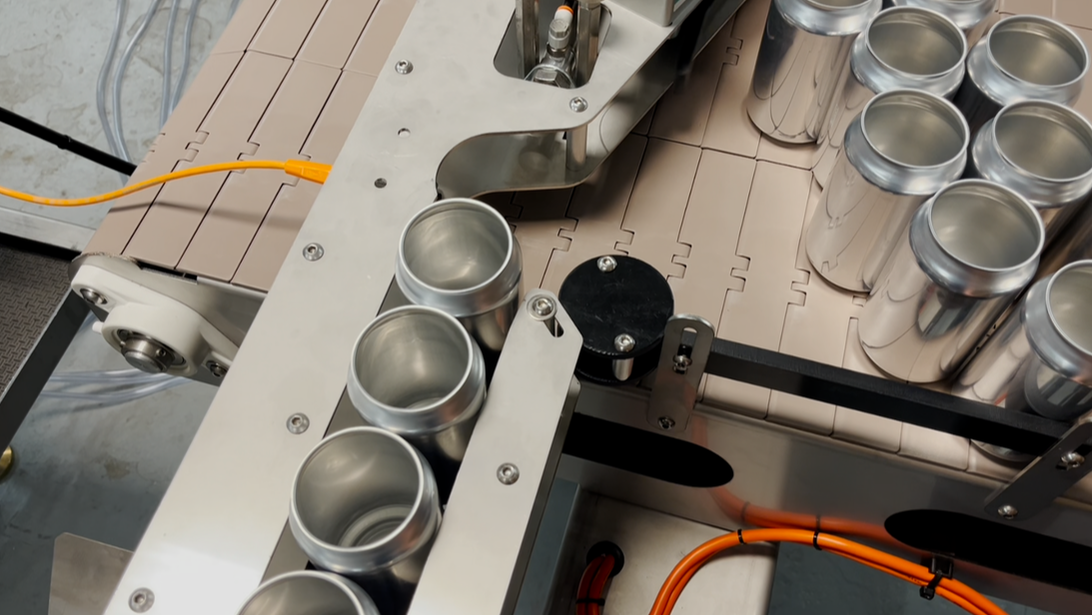

Aligning the Machine to the Conveyor

Learn how to level the machine and the conveyor to each other

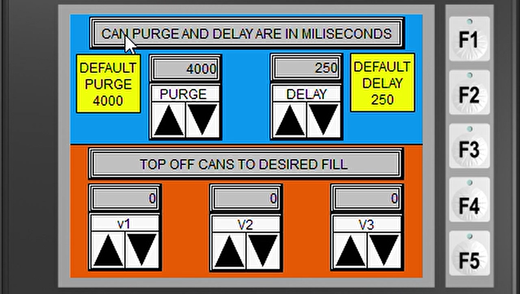

Replacing a Float on a Gen 2 Filler

Fixes a float that is stuck on or off regardless of fill level

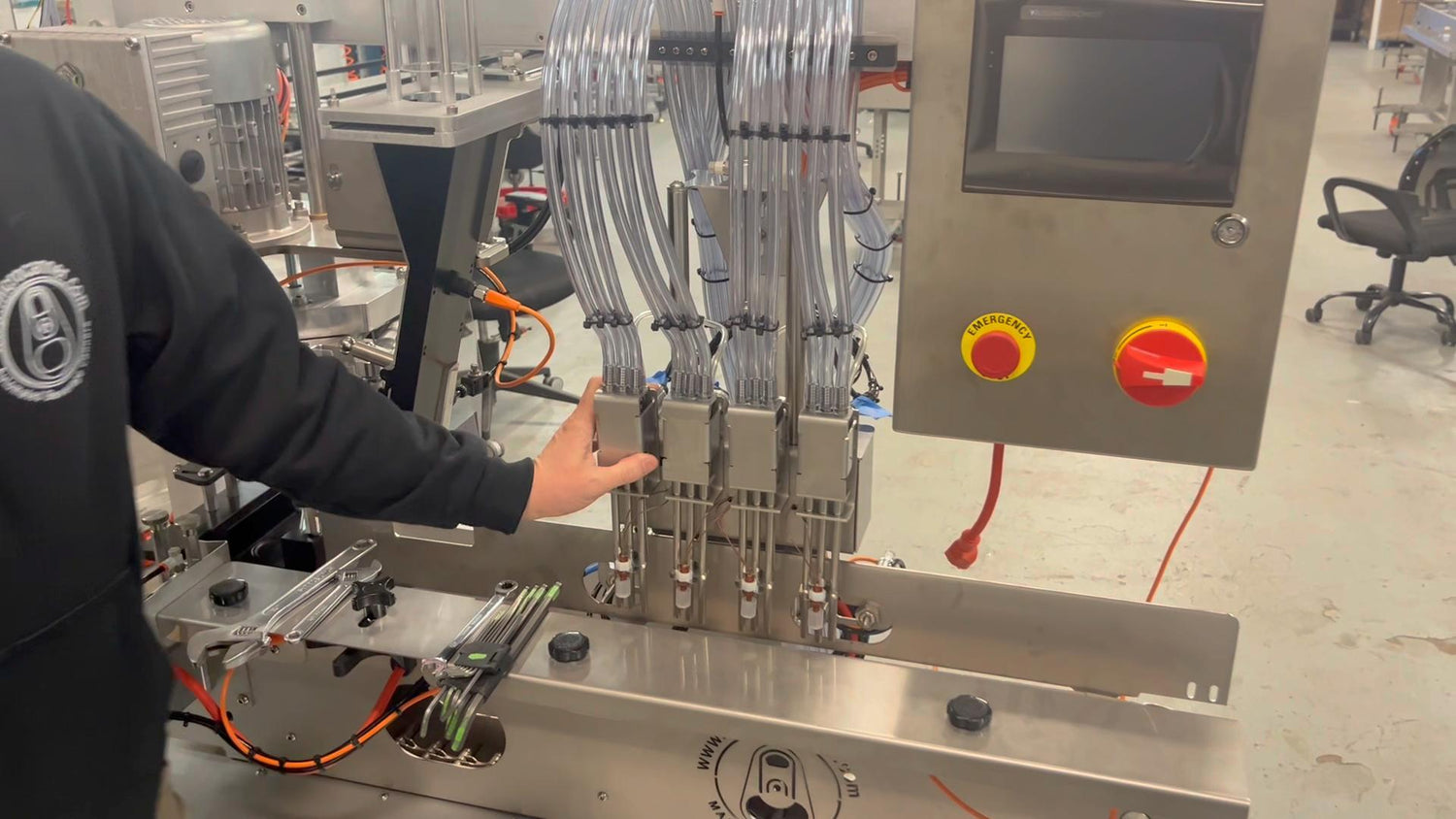

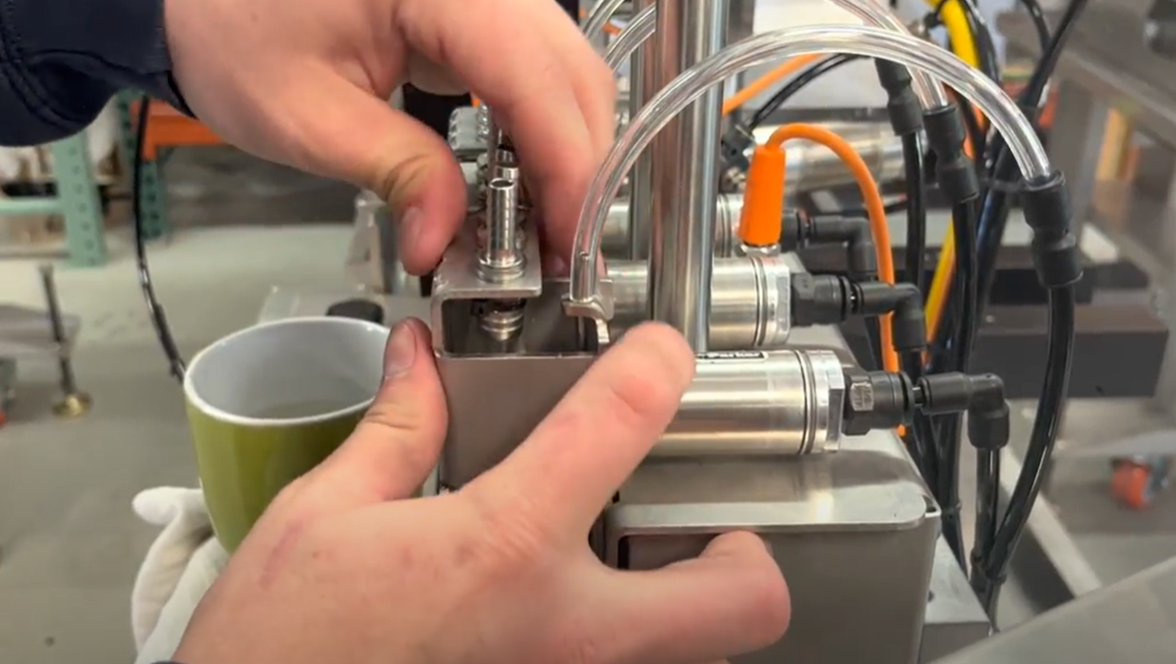

Gen 1 Filler Pinch Cylinder Replacement

Replace a sticking cylinder or leaking pinch valve cylinder

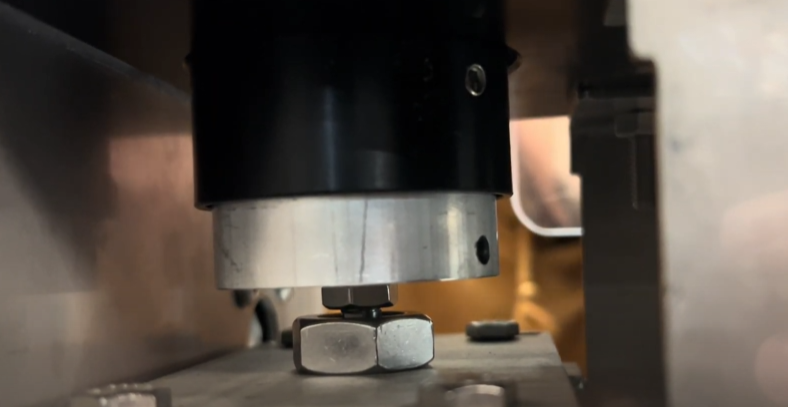

Adjusting Lift Puck Height

Fixes cans that crush or jam getting on or off of the lift puck

Index and Agitator Adjustment for Air Driven Agitators

Fixes cans becoming stuck and fixes inconsistent indexing

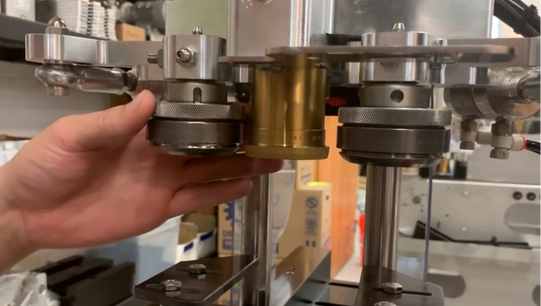

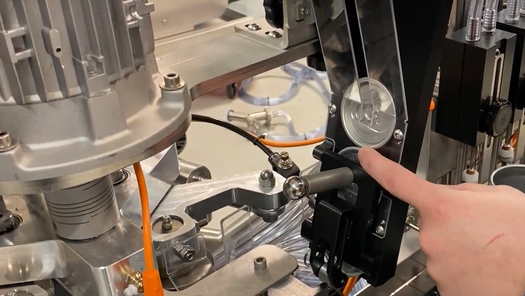

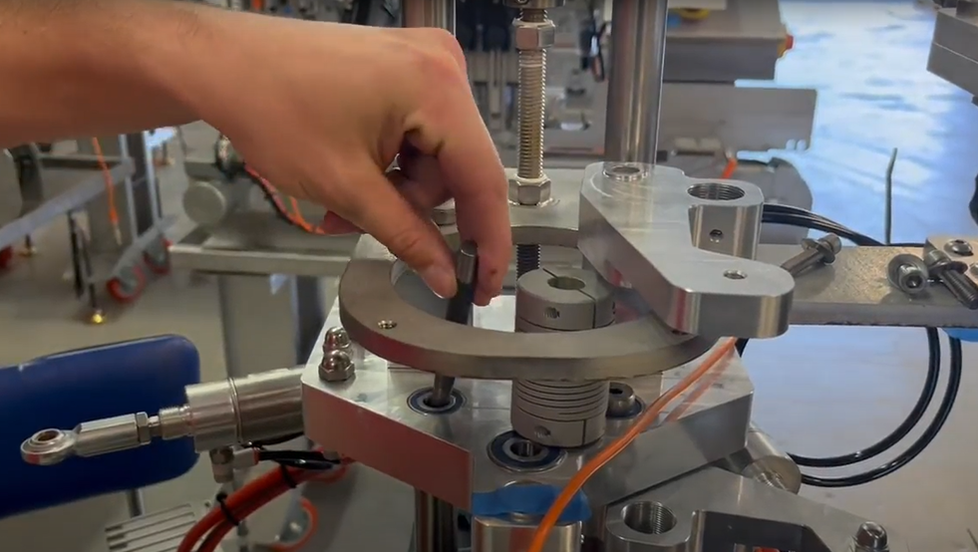

Replacing Seamer Arm Bearings

Fixes operation arms that don't extend smoothly or that deflect heavily

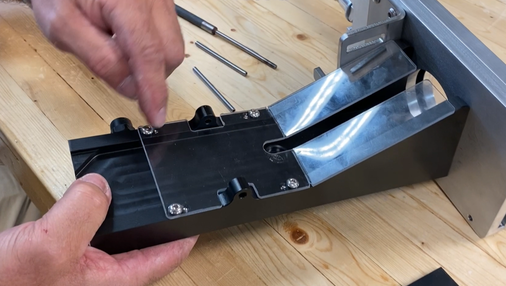

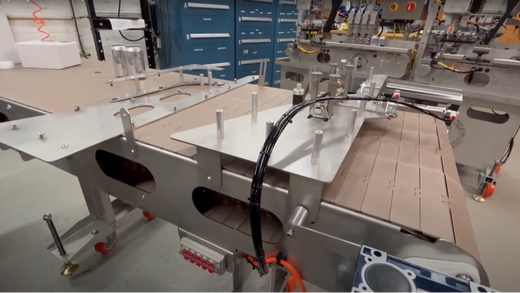

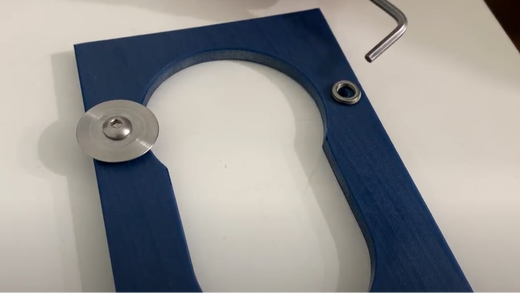

Replacing the Infeed Deck

Learn how to replace the infeed deck, needed for infeed deck machining to fit large date coder heads

Setting the Cap Shedder Speed

Can fix cap shedders that shed two lids when only one lid should be shed

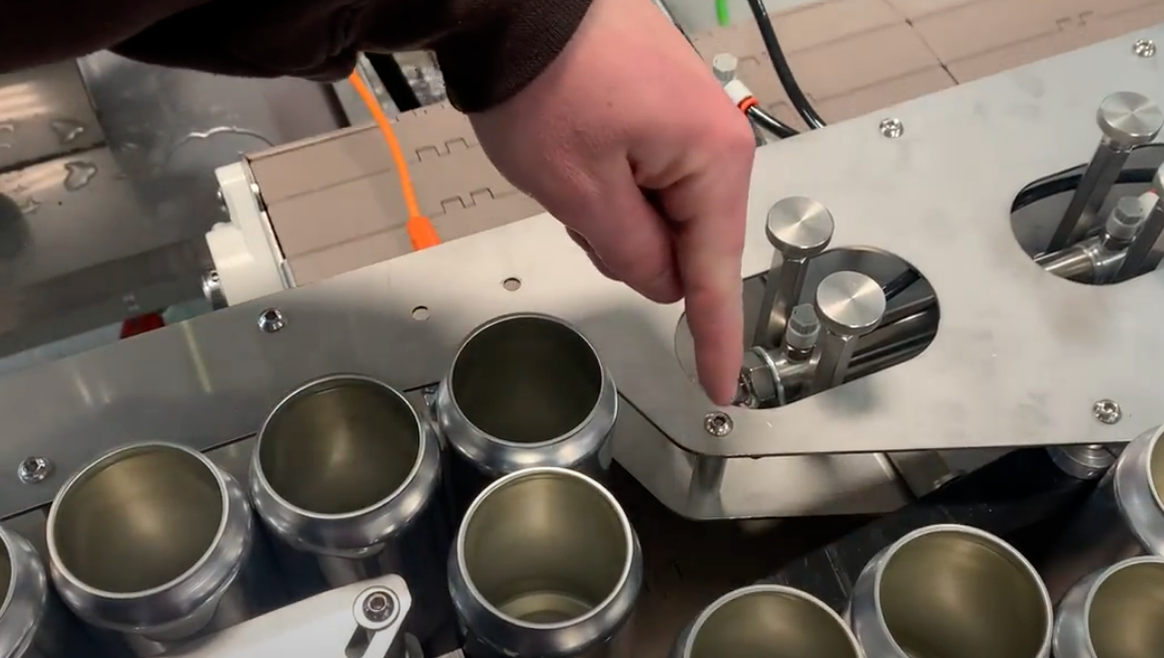

Complete Infeed Setup for Motor Driven Agitator

Teaches you how to setup your infeed, only for motor driven agitators

Adjusting for 88 Gauge Lids

Confirm you have 88 gauge lids before preforming the actions in this video. If you do have 88 gauge lids this will fix jamming and lids not shedding.

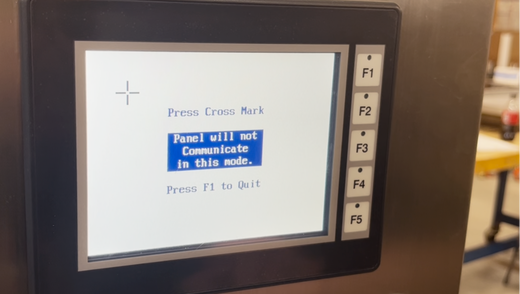

Calibrate Your Touchscreen

Fixes a touch screen that is no longer accurate to touch inputs

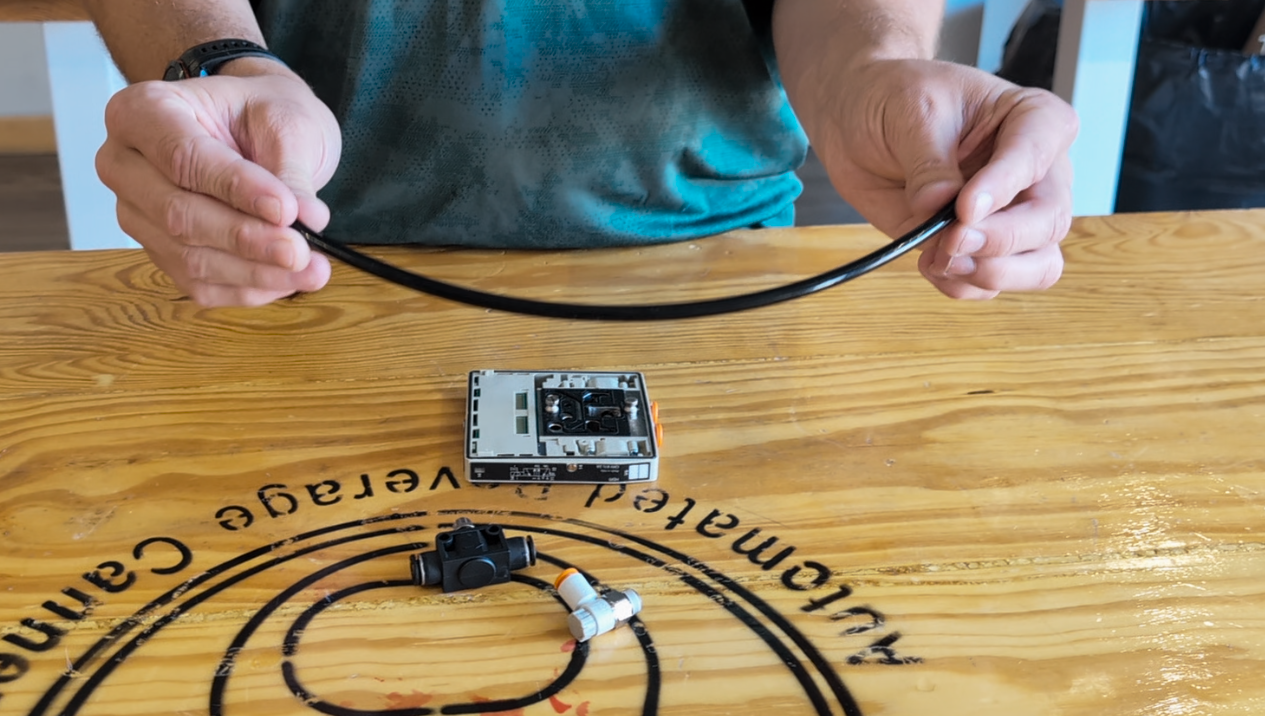

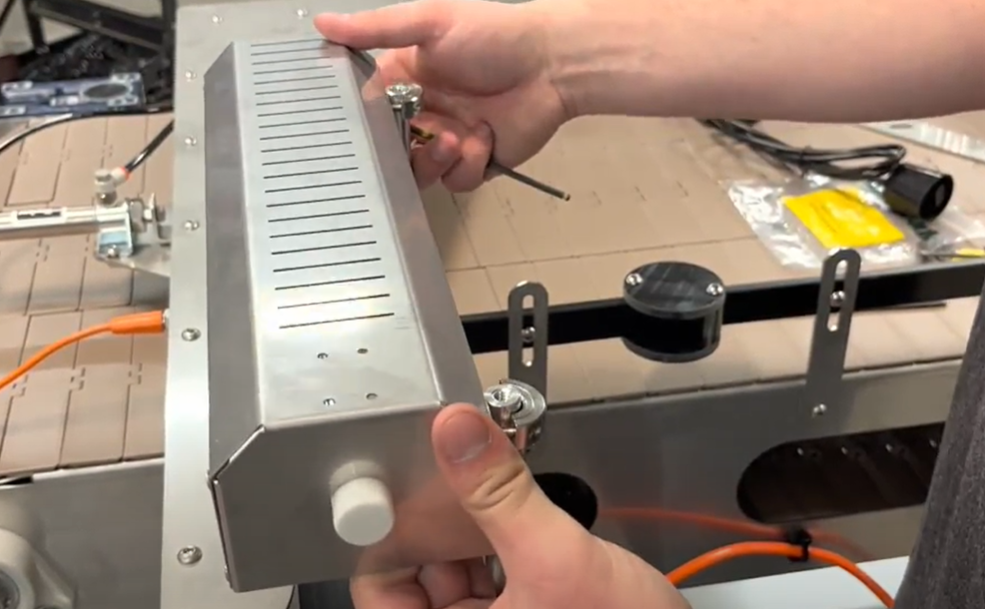

Adding an Exhaust card

This fixes valves and cylinders fluttering while other cylinders are activating or deactivating

Setting the Foam Rail height

Fixes cans crushing in the seamer and cans not indexing correctly

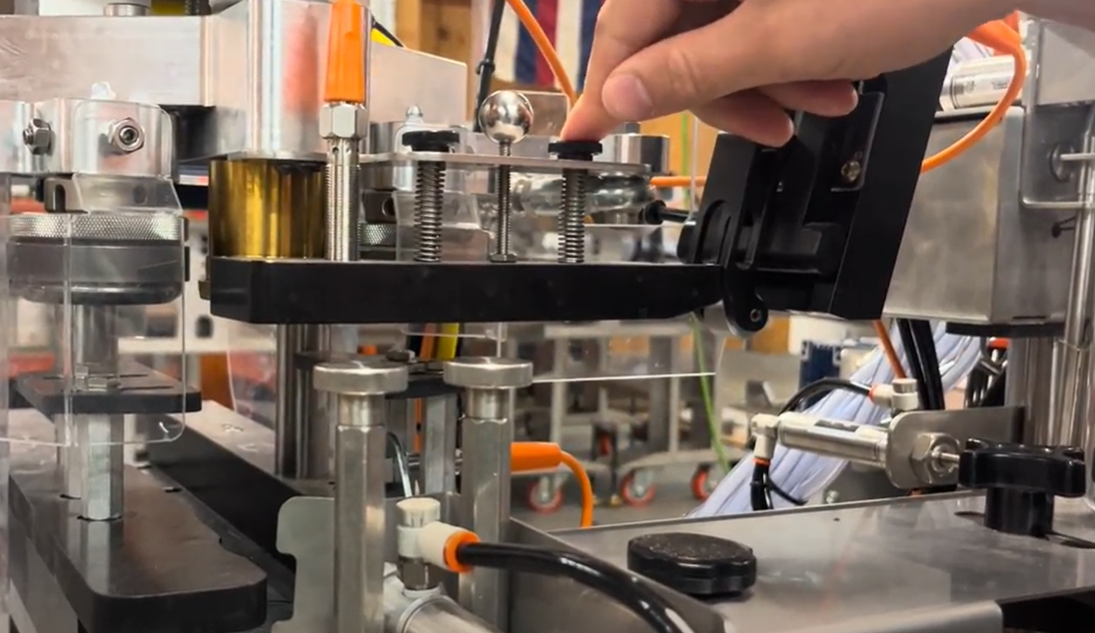

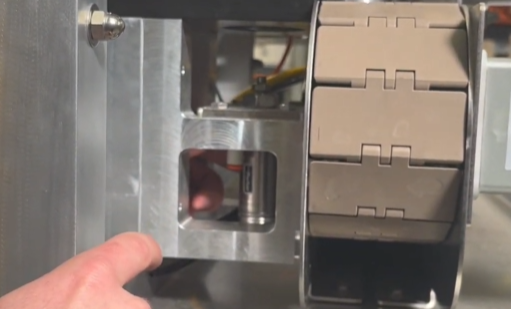

Cap In Place Sensor Adjustment

Fixes a cap in place sensor that's not sensing can lids or that is sensing when no lid is present.