MC-FLEX Videos

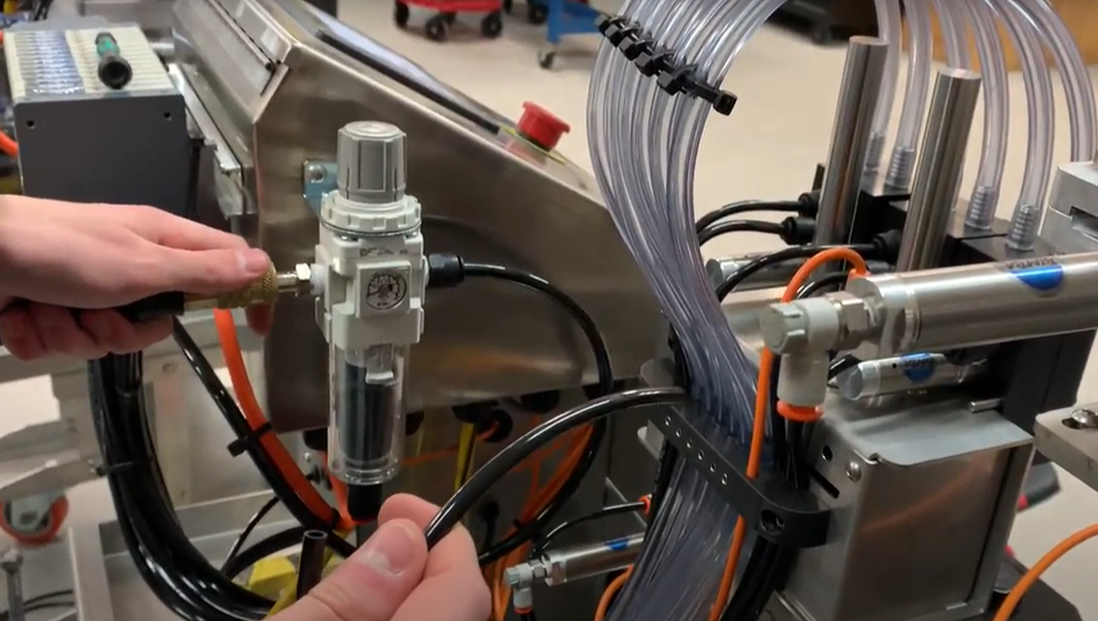

How to Drain your Air Compressor

Prevents air cylinders speed from changing and helps prevent flow controls becoming inoperable

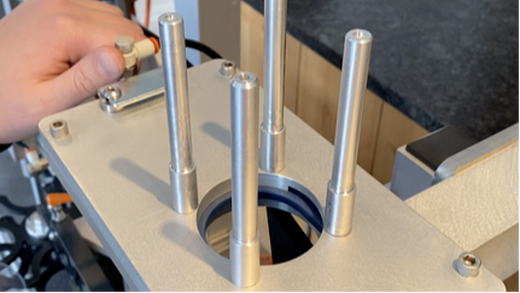

Setting Cylinder Speeds

Learn how to change the speeds of the air cylinders on your machine

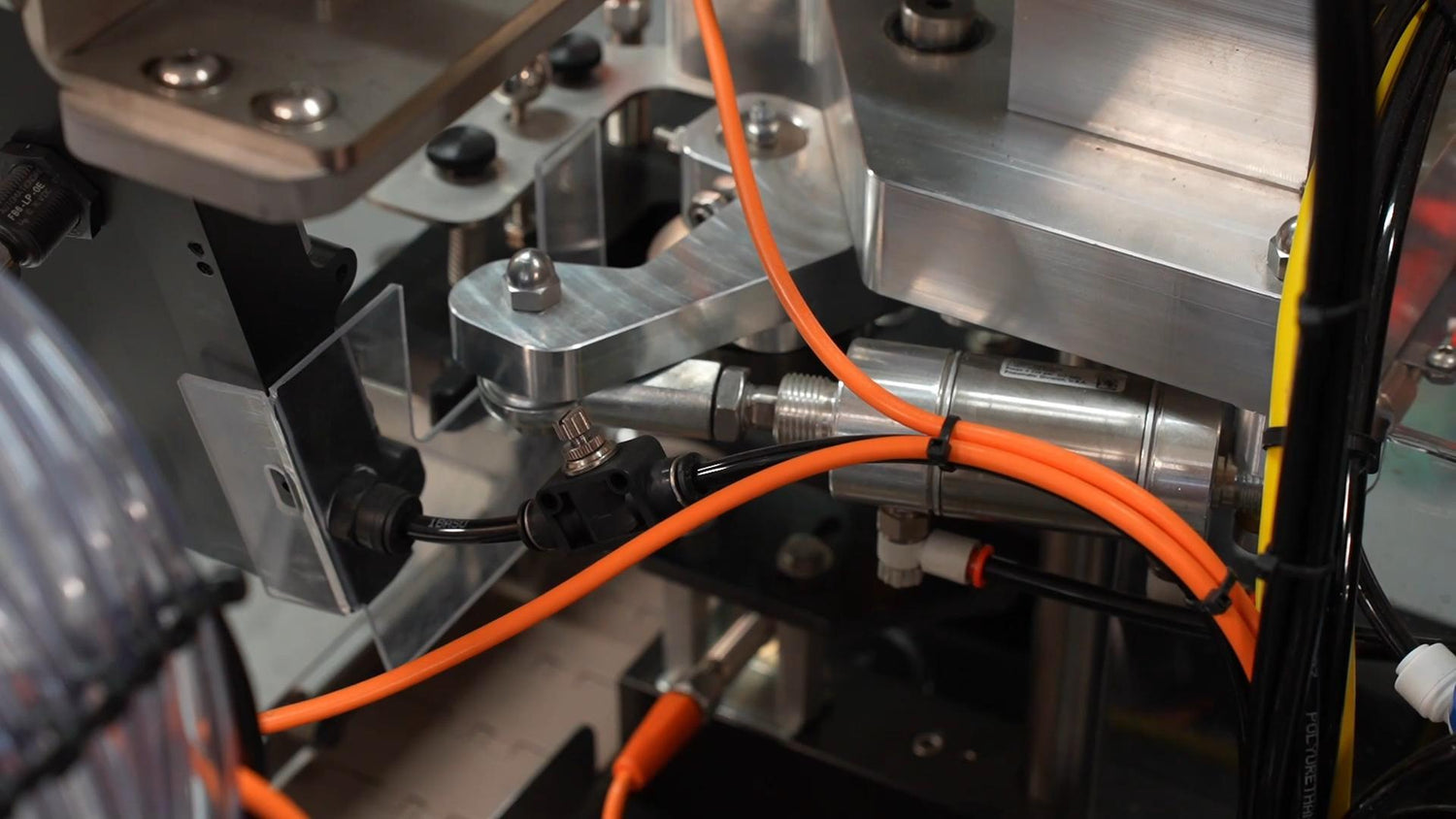

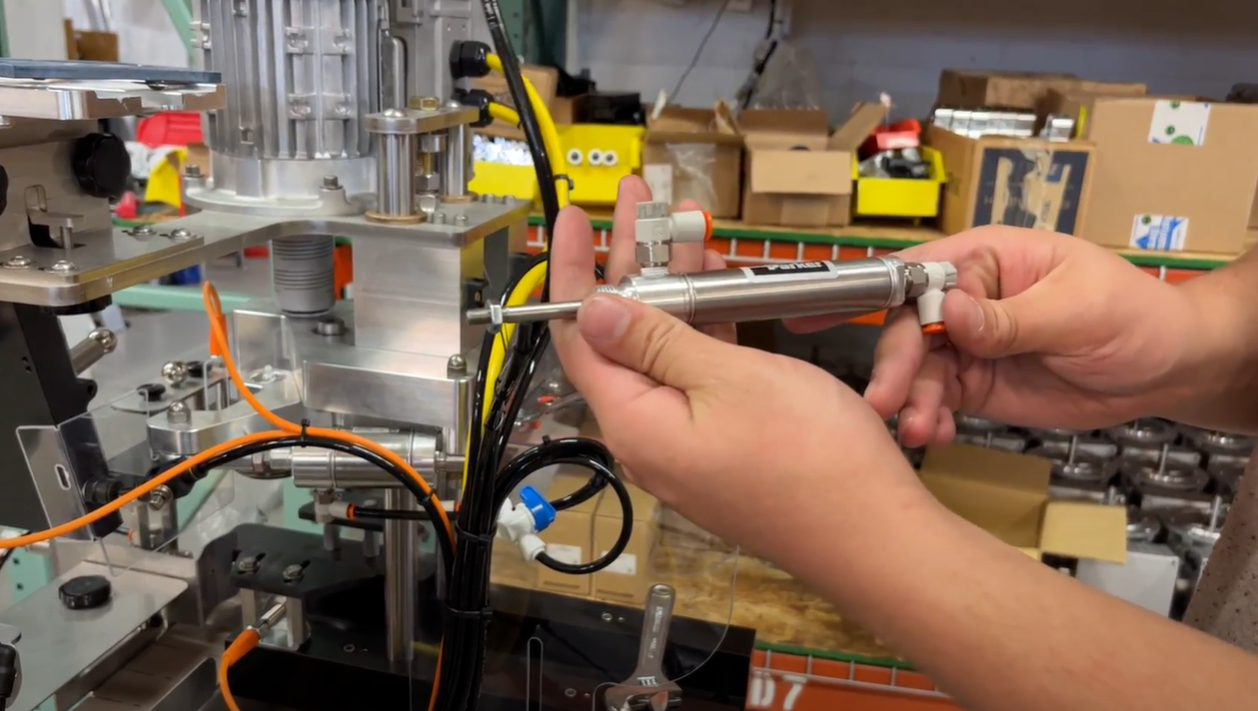

Leak Testing a Cylinder

Can diagnose a bad air cylinder. Bad air cylinders will extend and or retract inconsistently.

Cleaning and Lubricating a Cylinder

Keep your cylinders from going bad, learn how to clean and lubricate them

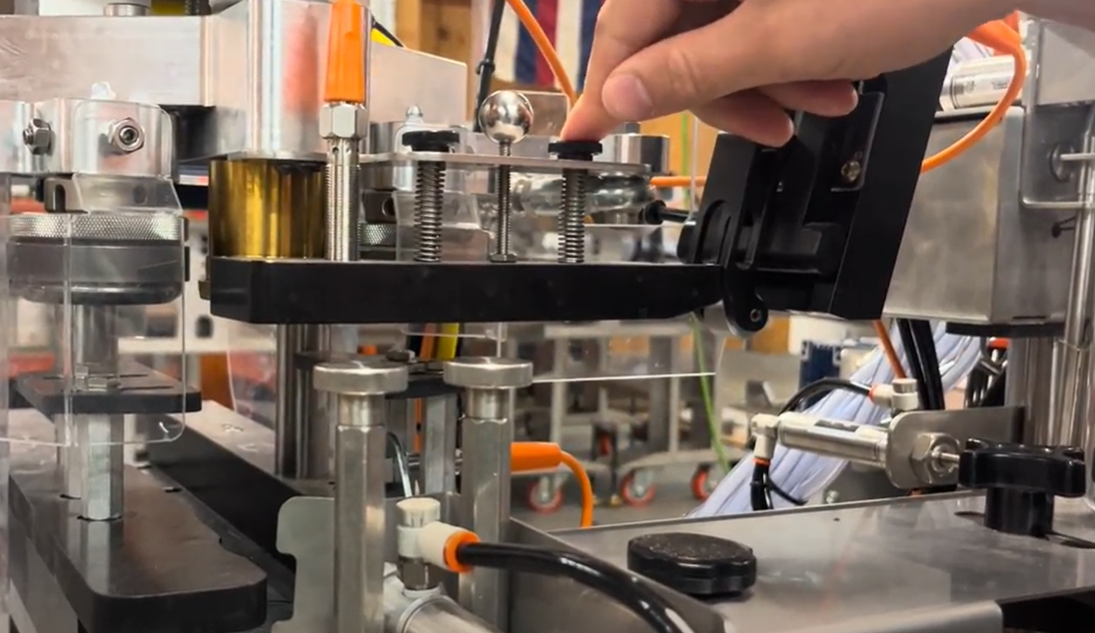

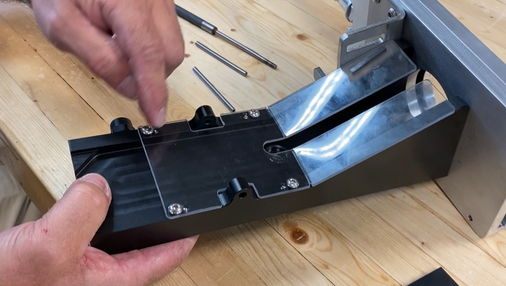

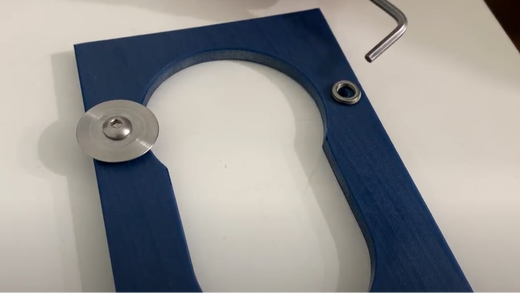

Flipping the Cap shedder plate

This can extend the life of a cap shedder plate that is starting to get worn out. This can fix inconsistent lid dropping and lid jamming

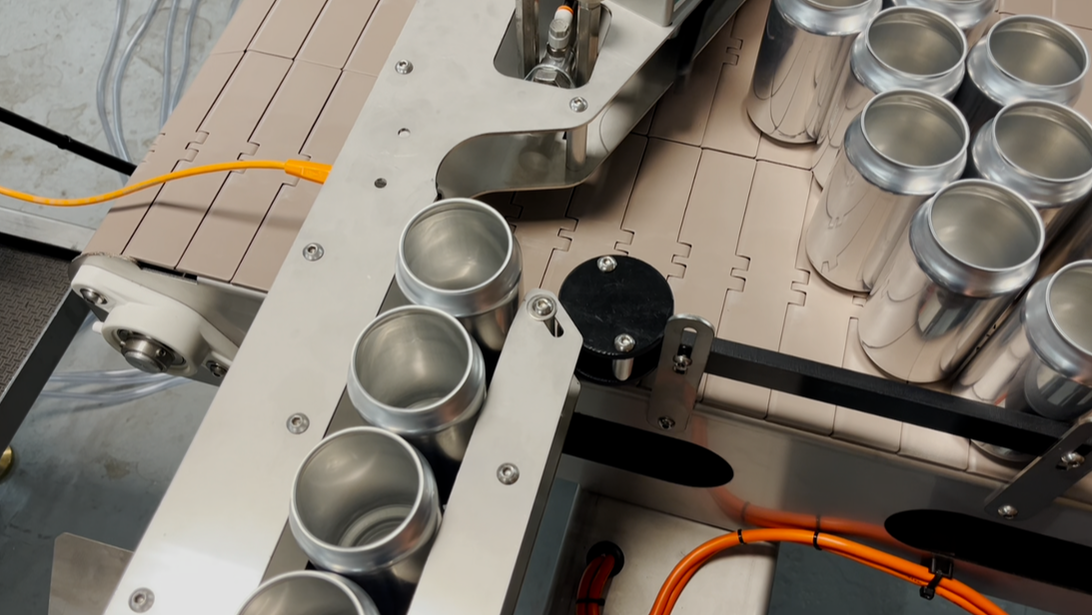

Switching between Can sizes

Teaches you how to adjust the machine to run different size cans

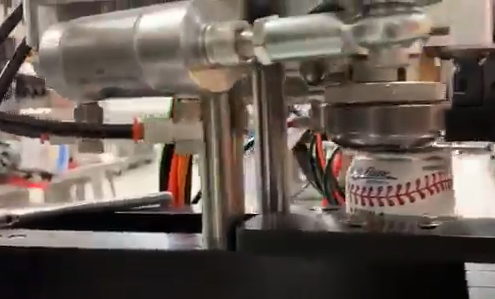

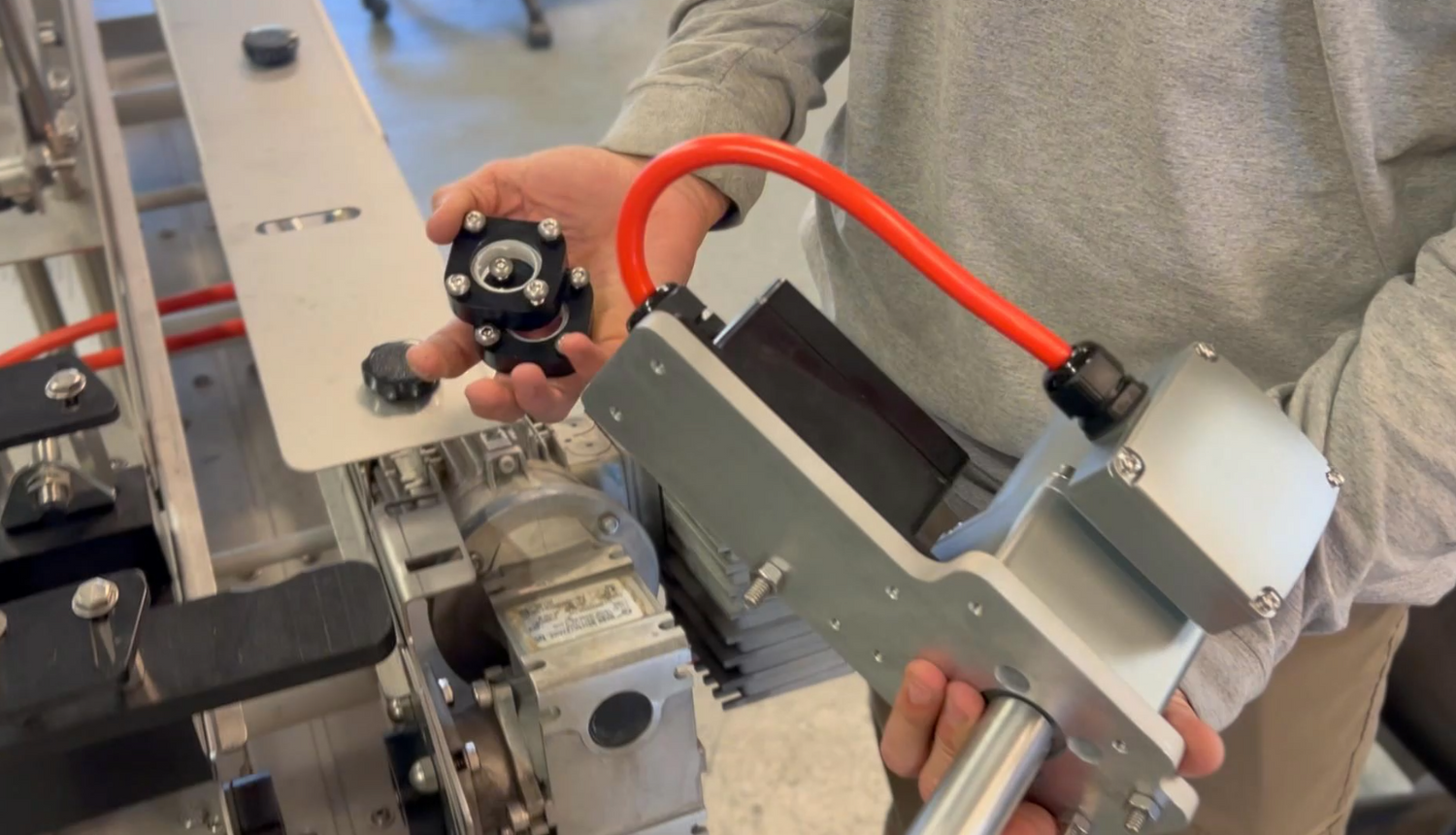

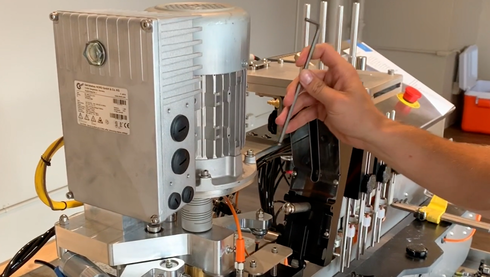

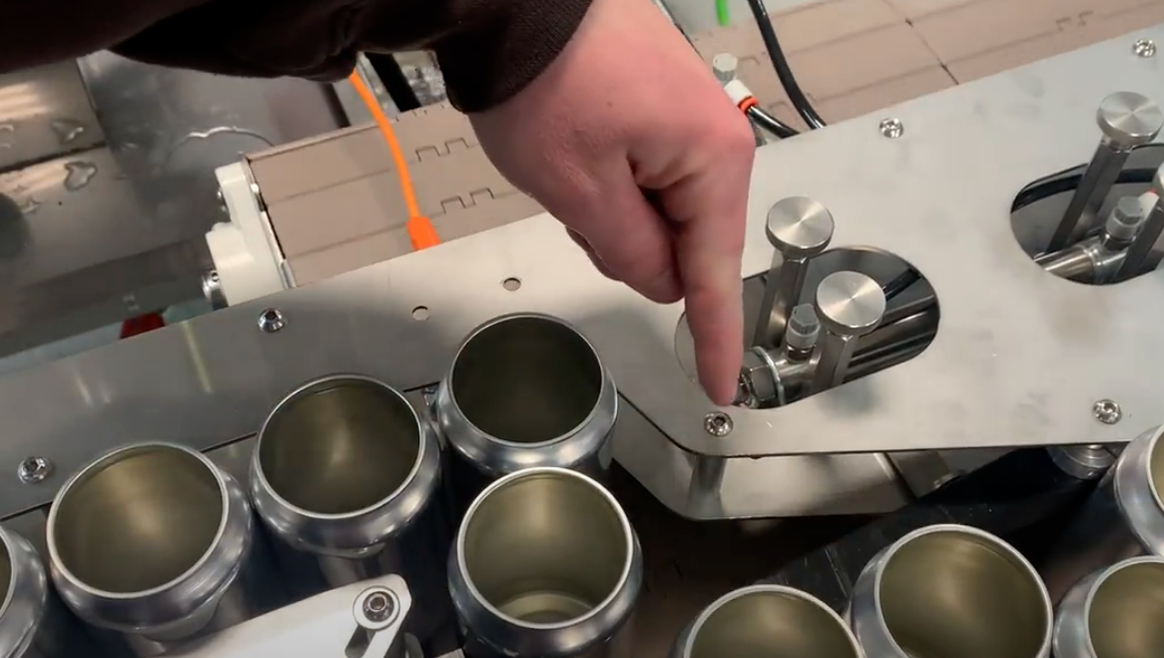

Polishing a Chuck

Fixes cans getting stuck on the chuck and causing jamming in the seamer

Replacing a Float on a Gen 2 Filler

Fixes a float that is stuck on or off regardless of fill level

Replacing a Float on a Gen 1 filler

Fixes a float that is stuck on or off regardless of fill level

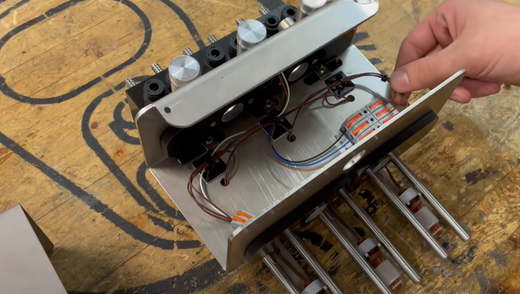

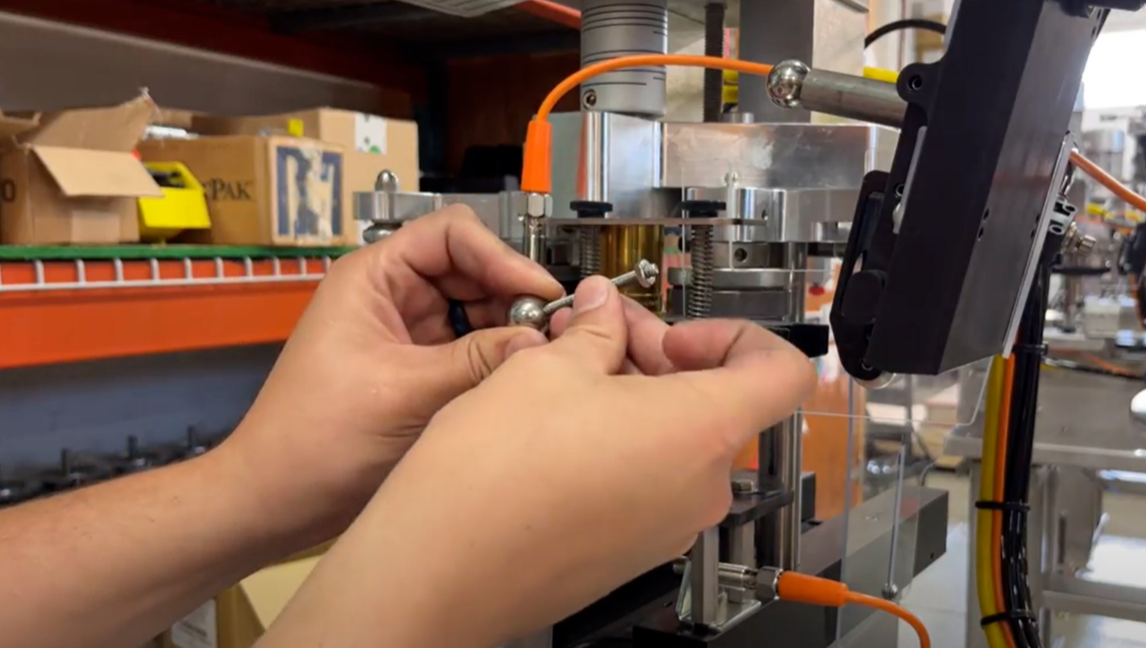

Gen 1 Filler Pinch Cylinder Replacement

Replace a sticking cylinder or leaking pinch valve cylinder

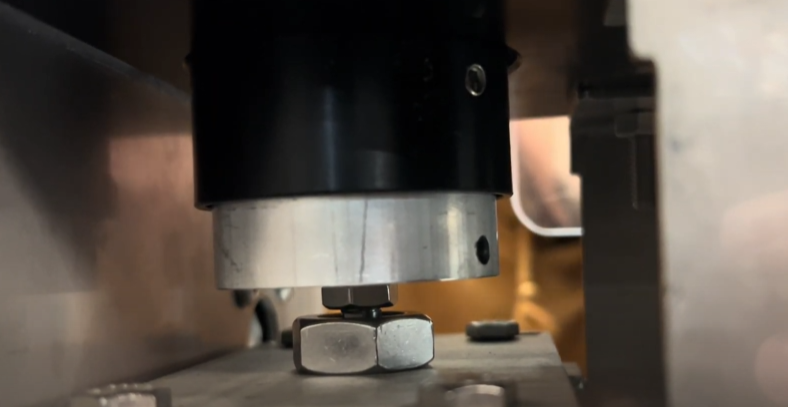

Setting Operation Heights

Fixes incorrect seam heights, can even fix motor stalling while seaming

Replacing UNSEALED Seamer Bearings

Fixes a loud seamer and can fix inconsistent seams. ONLY for machines still using unsealed bearings. If you have a grease zerk on the front of the seamer block and grease the bearings then your bearings are UNSEALED

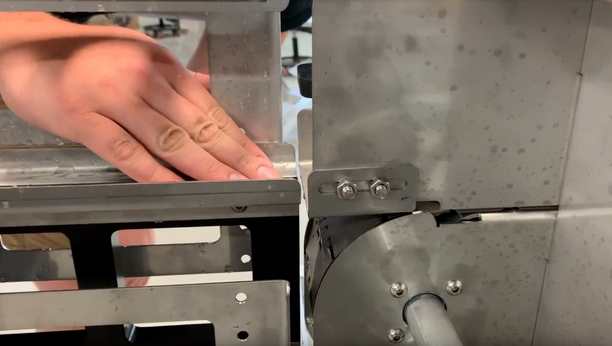

Aligning the Machine and Infeed

Teaches you how to properly align your infeed to the machine. This is only for older machines using a shaft to drive the infeed

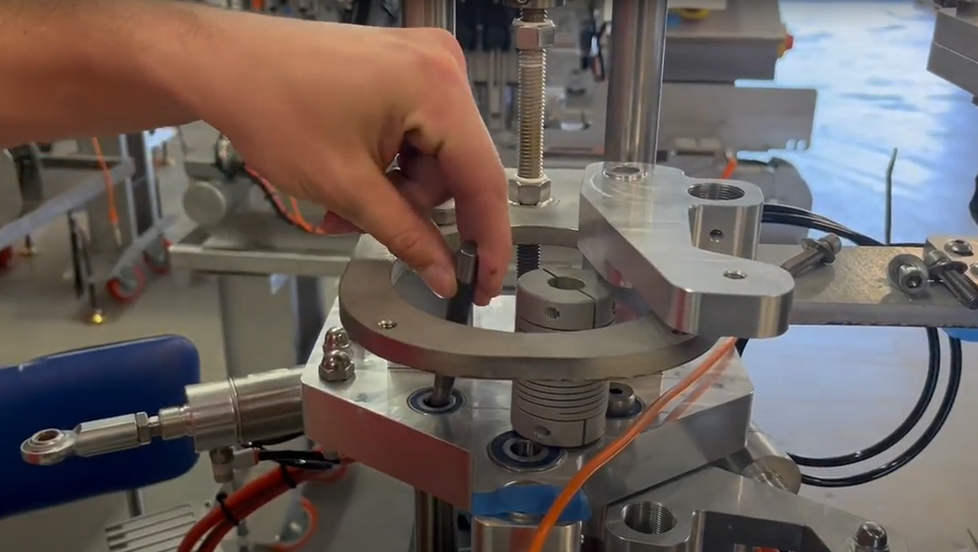

Operation Tooling Teardown

Fixes the operation not spinning. Please do not preform the actions in this video unless specifically instructed by a technician

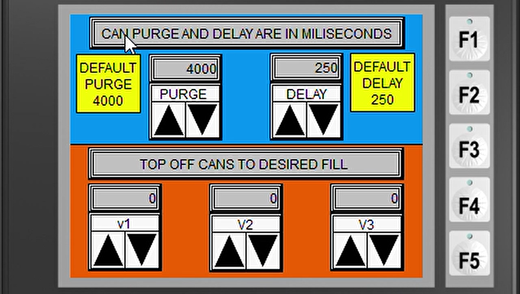

Setting the Cap Shedder Speed

Can fix the cap shedder shedding two lids when only one should have been shed

Adjusting Infeed Index and Agitator for Air Driven Agitator

Fixes cans not getting unstuck and inconsistent index's into the rinser

Adjusting for 88 Gauge Lids

Confirm you have 88 gauge lids before preforming the actions in this video. If you do have 88 gauge lids this will fix jamming and lids not shedding.

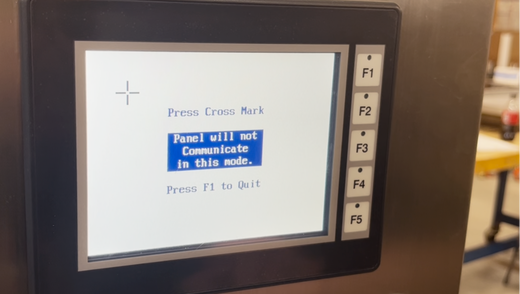

Calibrate Your Touchscreen

Fixes an inaccurate touch screen that is not picking up touch inputs accurately

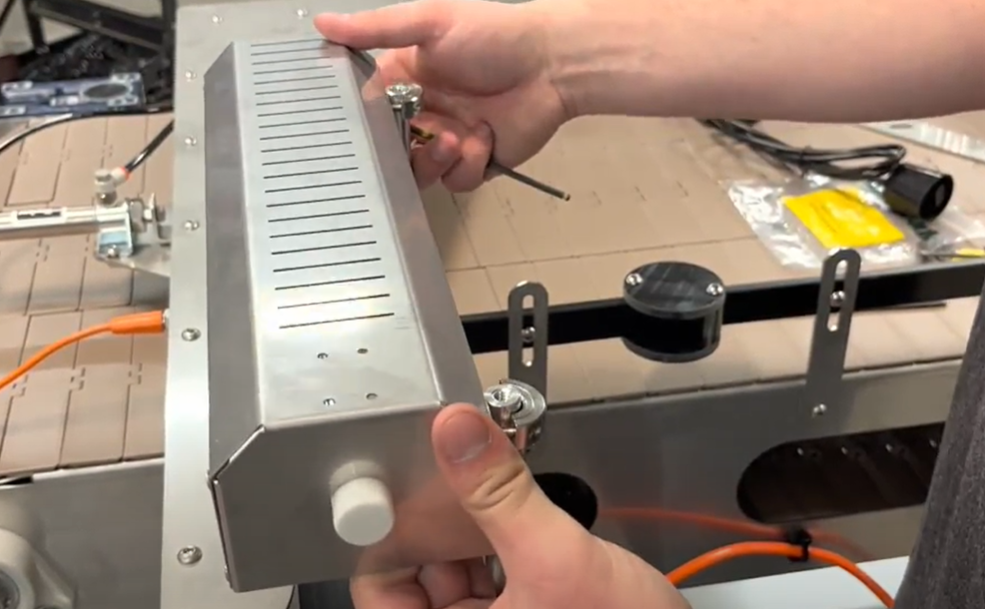

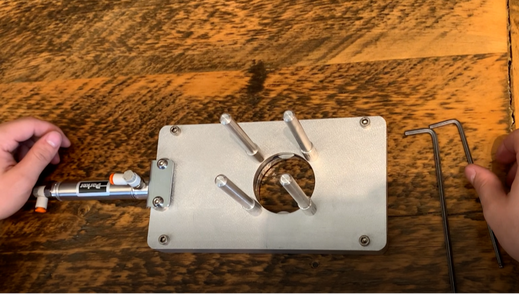

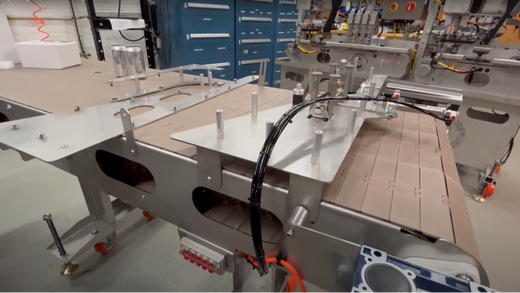

Replacing Your Infeed Deck

Instructs you how to replace your infeed deck, important if it needs machining to fit a date coder

Installing a Sneed Printer

A modified deck plate may be required to install a sneed printer. Contact a microcanner technician for more information

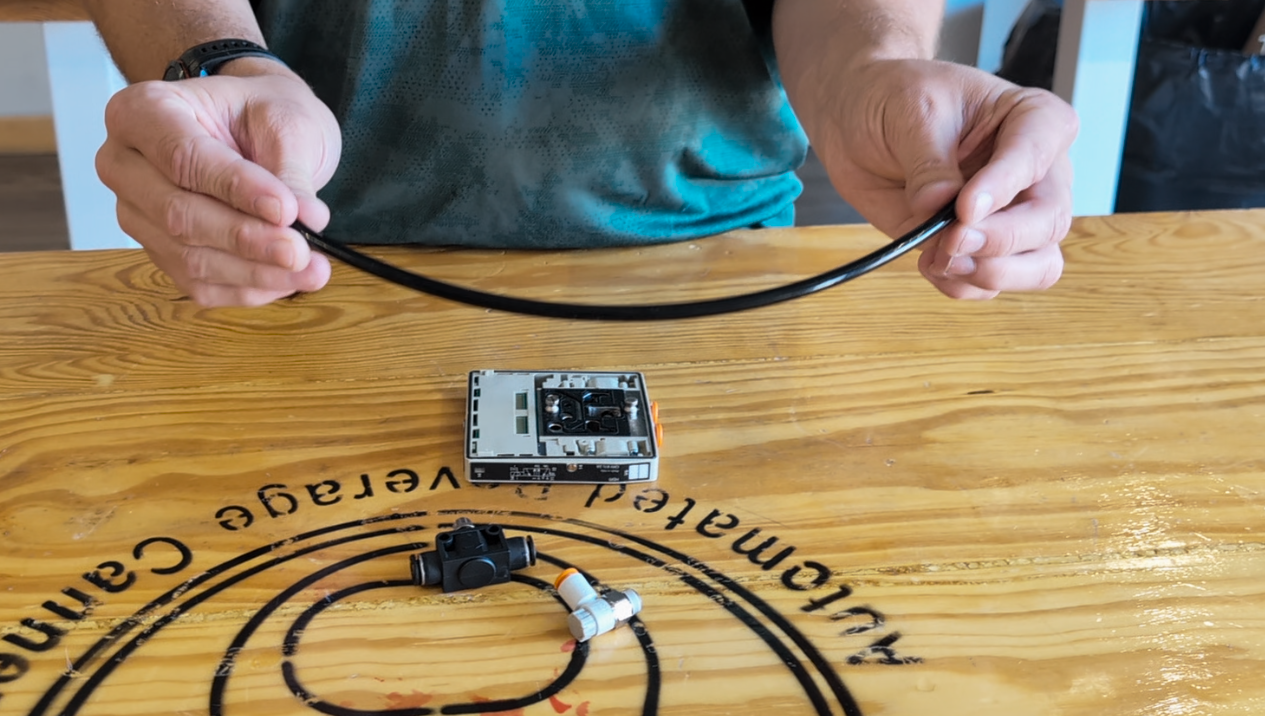

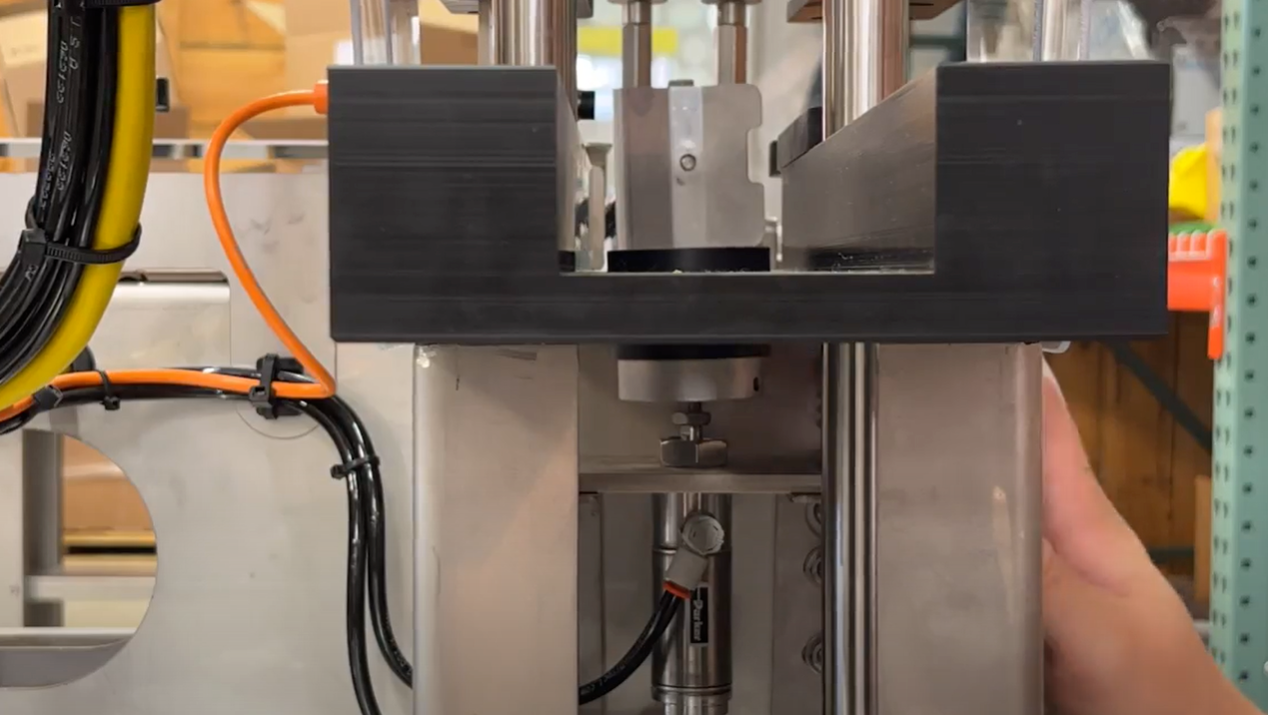

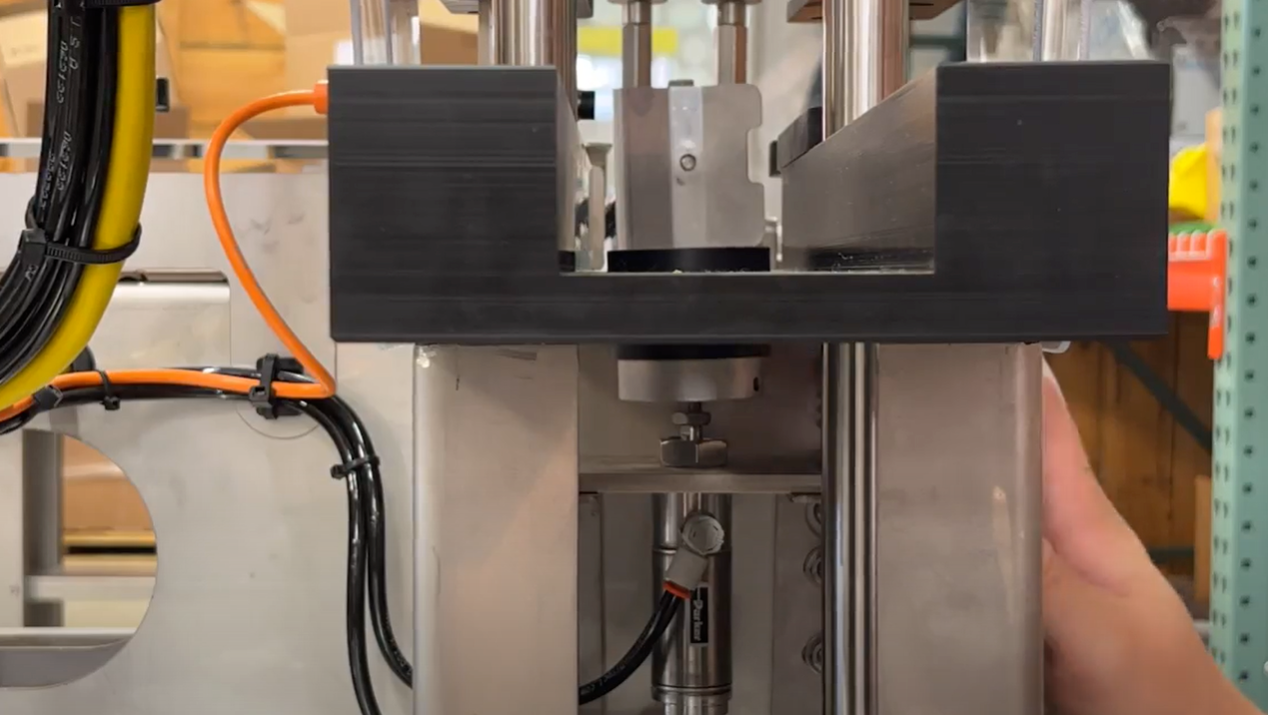

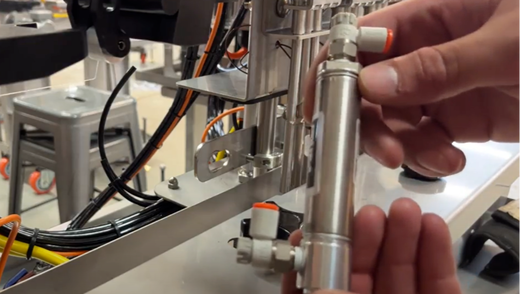

Replacing the Lift Puck Cylinder

Fixes a lift puck cylinder that is leaking and or raising or lower too slowly

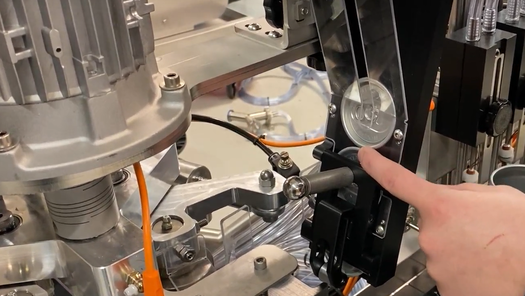

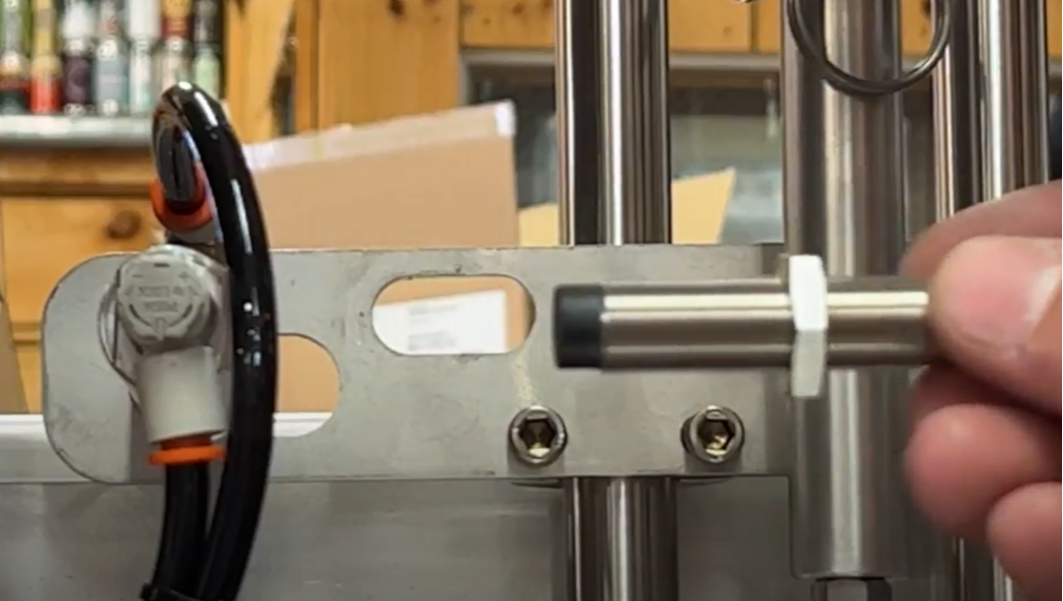

Cap In Place Sensor Adjustment

Fixes a cap in place sensor that's not sensing can lids or that is sensing when no lid is present.

Replacing Cap Shedder Sensor

Fixes a sensor that is not reliably seeing a lid in front of it even after a cleaning

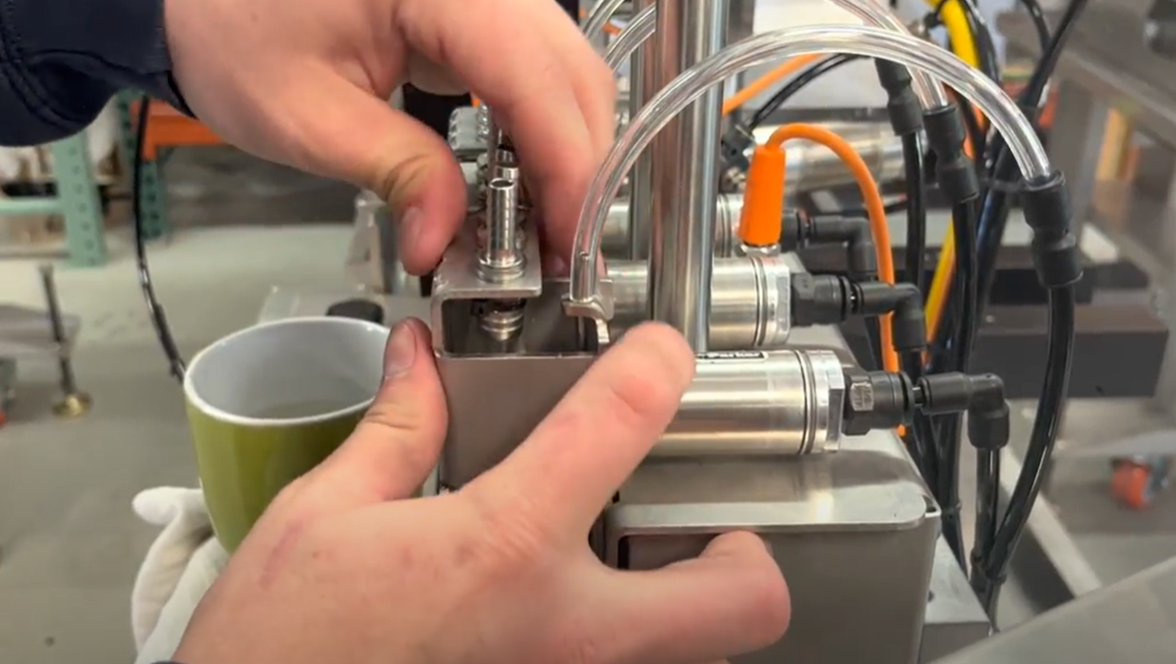

Replacing the Filler Lift Cylinder

Fixes a leaking filler lift cylinder that may not be smoothly raising and or lowering

Replacing the Filler Ready Sensor

Fixes a fill sensor that is not sensing even with a can on the tip of the sensor

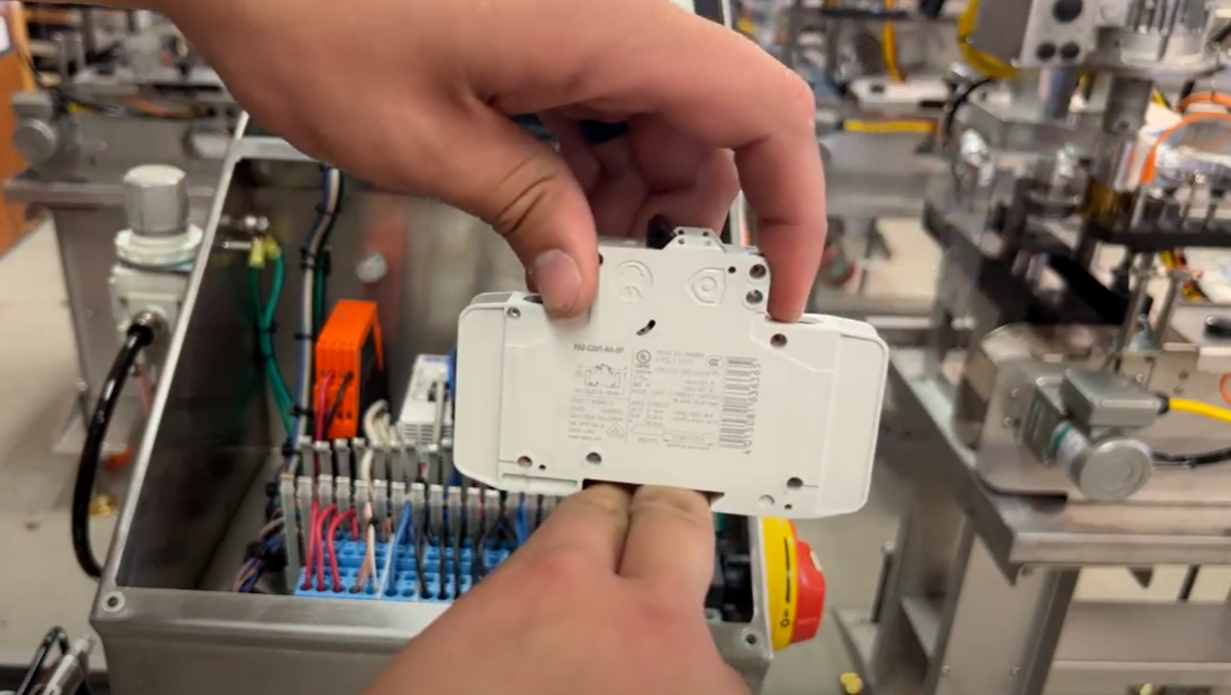

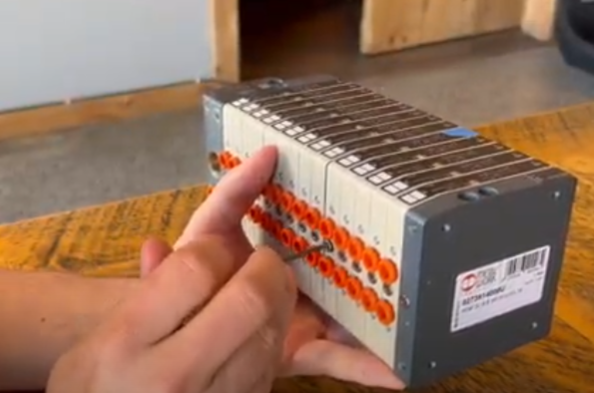

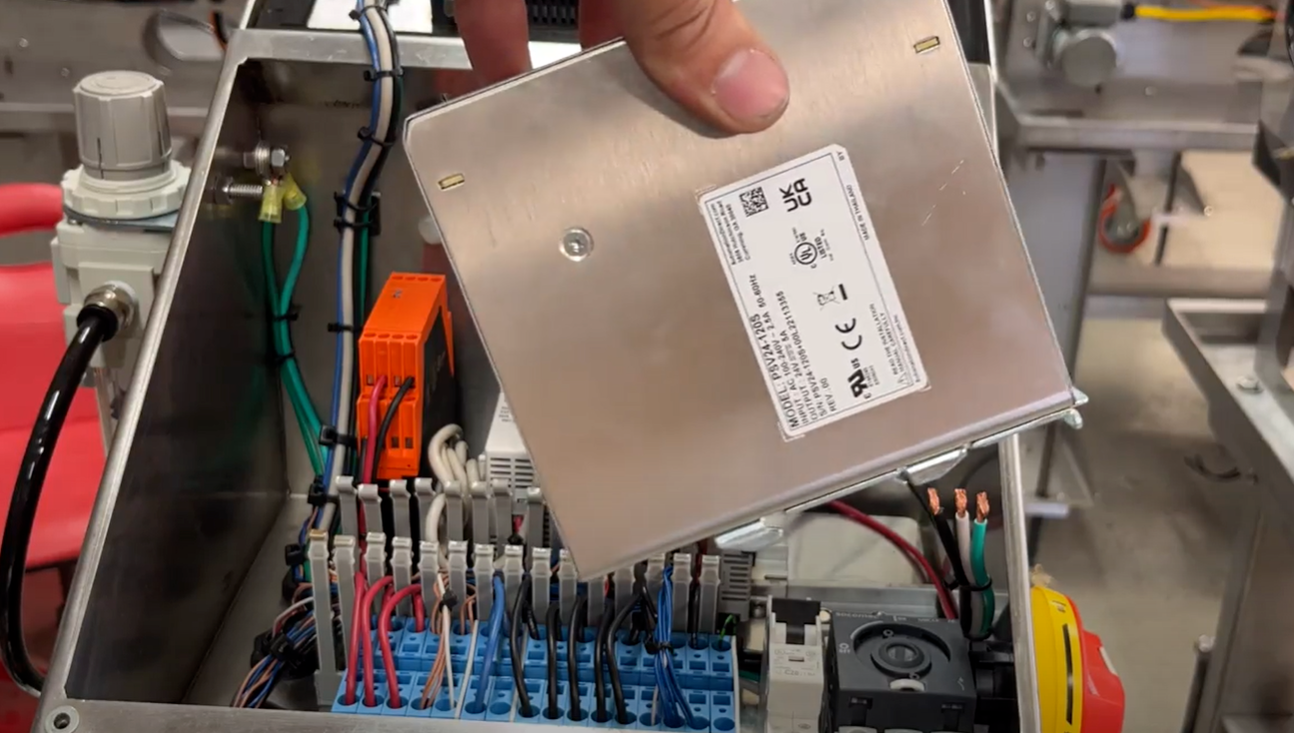

Replacing the PLC

Some plc failures will result in an error light being displayed, other failures can be a output on the plc itself being stuck on or stuck off

Replacing the Safety Relay

Fixes motor power and safe power not turning on even though all power is secured on the safety relay