MC-SWIFT Videos

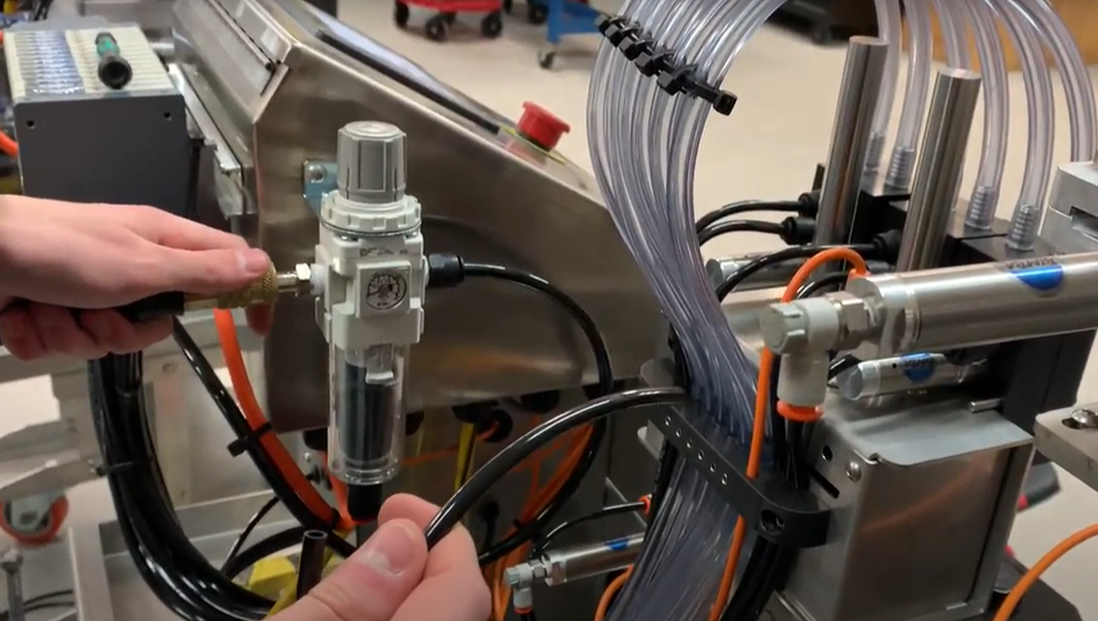

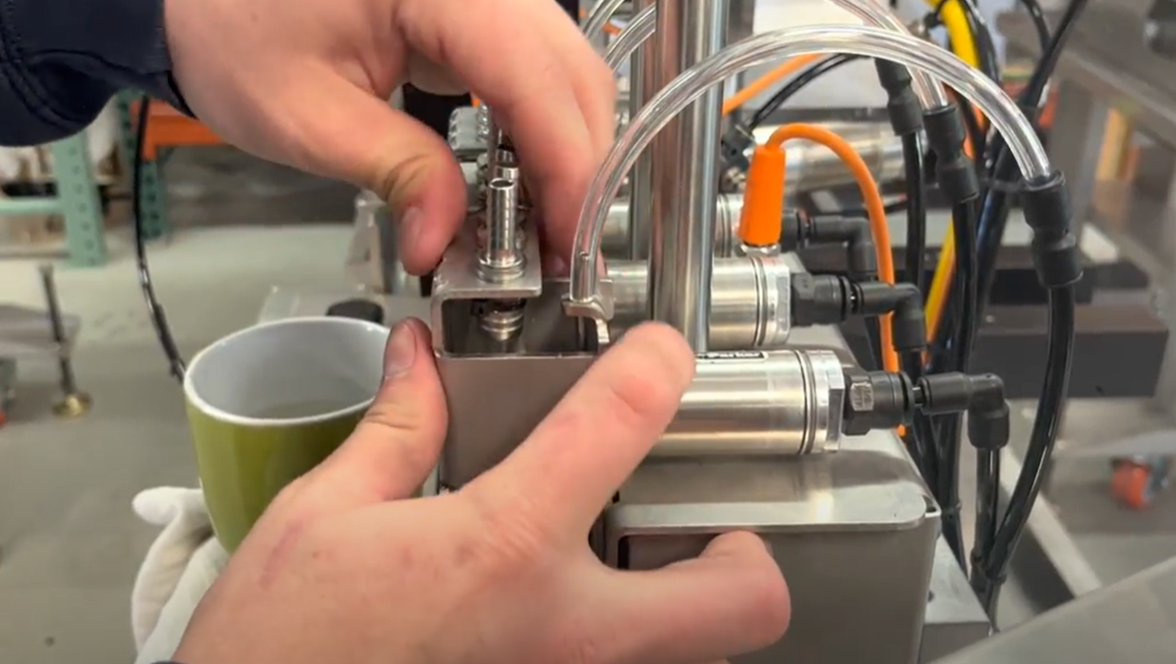

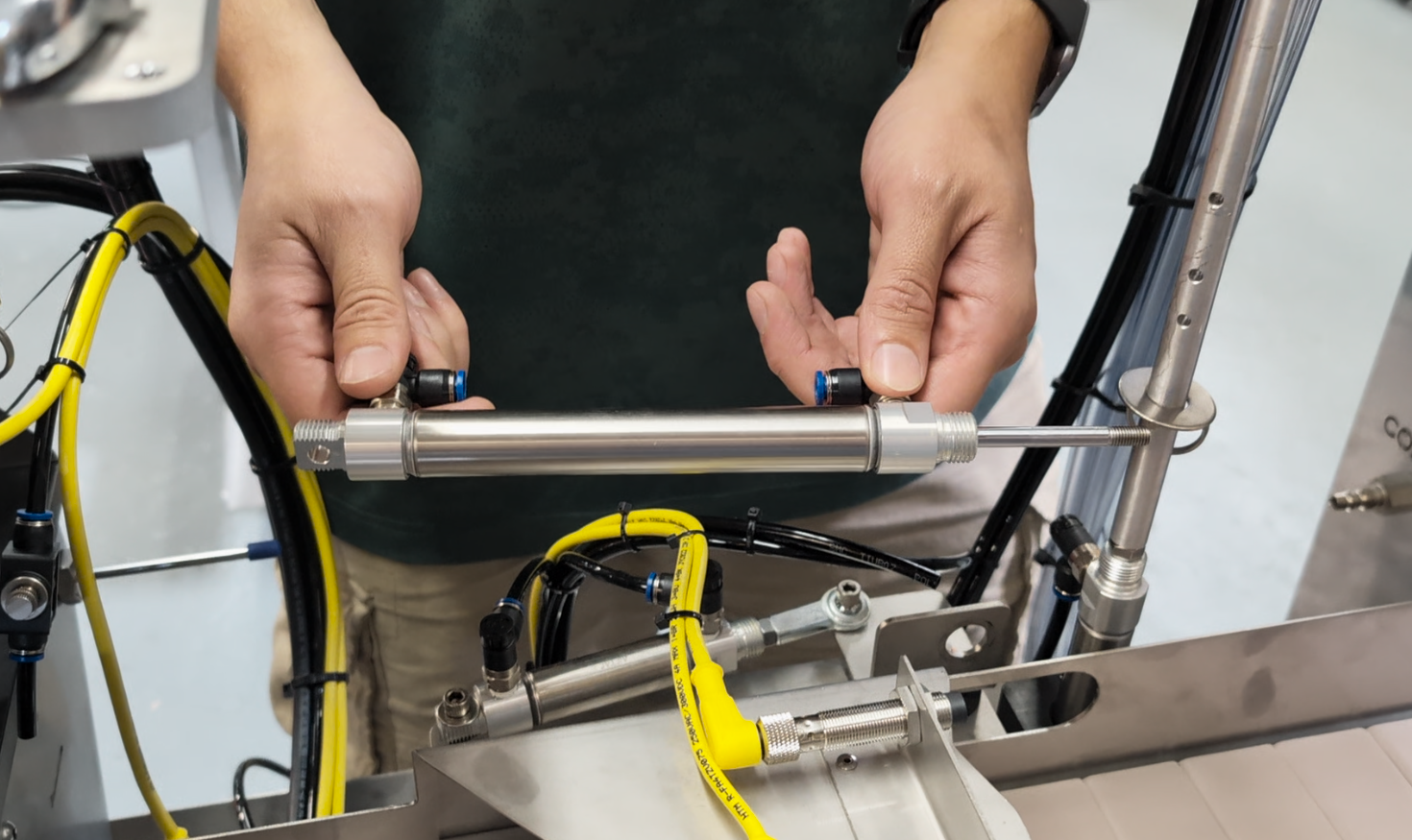

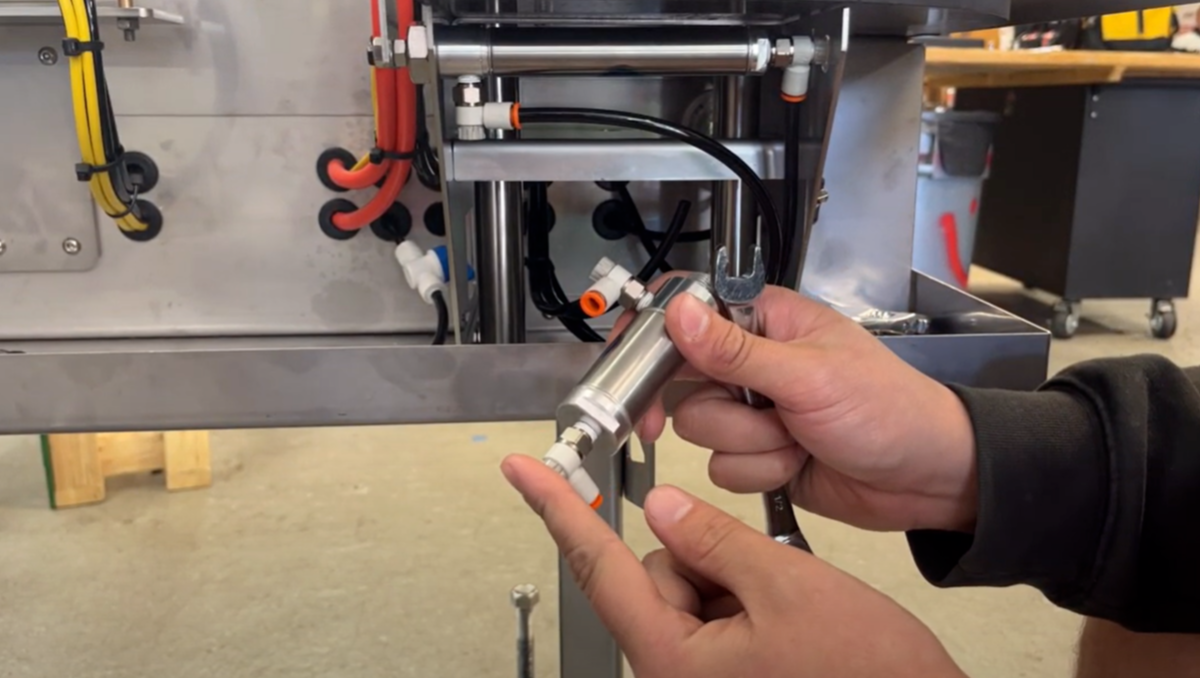

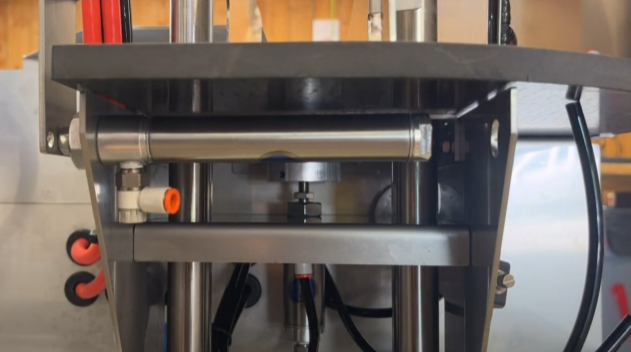

Cleaning and Lubricating a Cylinder

Keep your cylinders from going bad, learn how to clean and lubricate them

How to Drain your Air Compressor

Prevents air cylinders speed from changing and helps prevent flow controls becoming inoperable

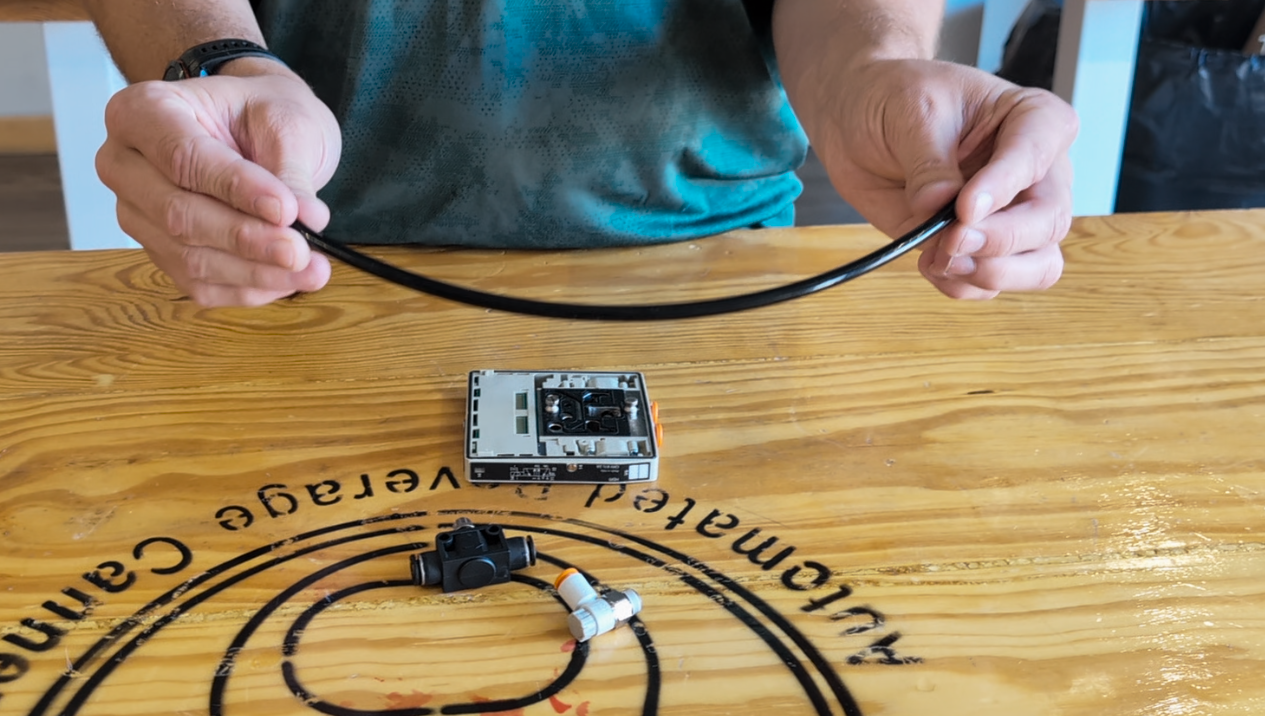

Leak Testing a Cylinder

Can diagnose a bad air cylinder. Bad air cylinders will extend and or retract inconsistently.

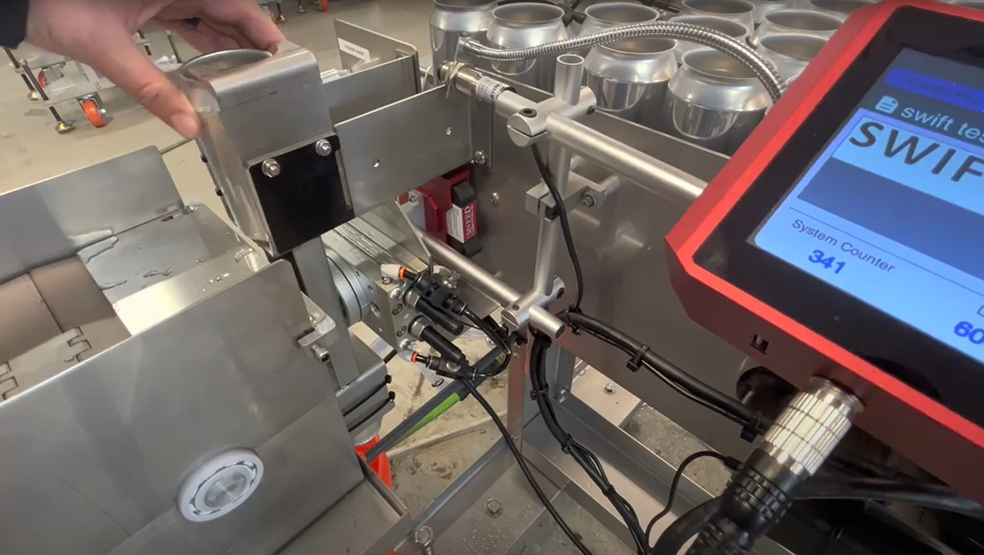

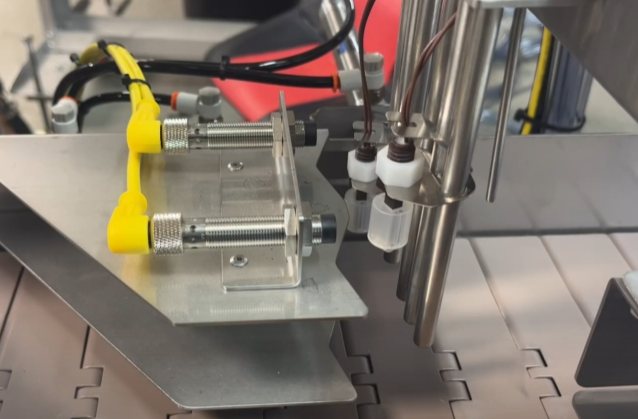

Installing a Sneed Printer on the Swift Infeed

Teaches you how to install a sneed printer onto your swift infeed

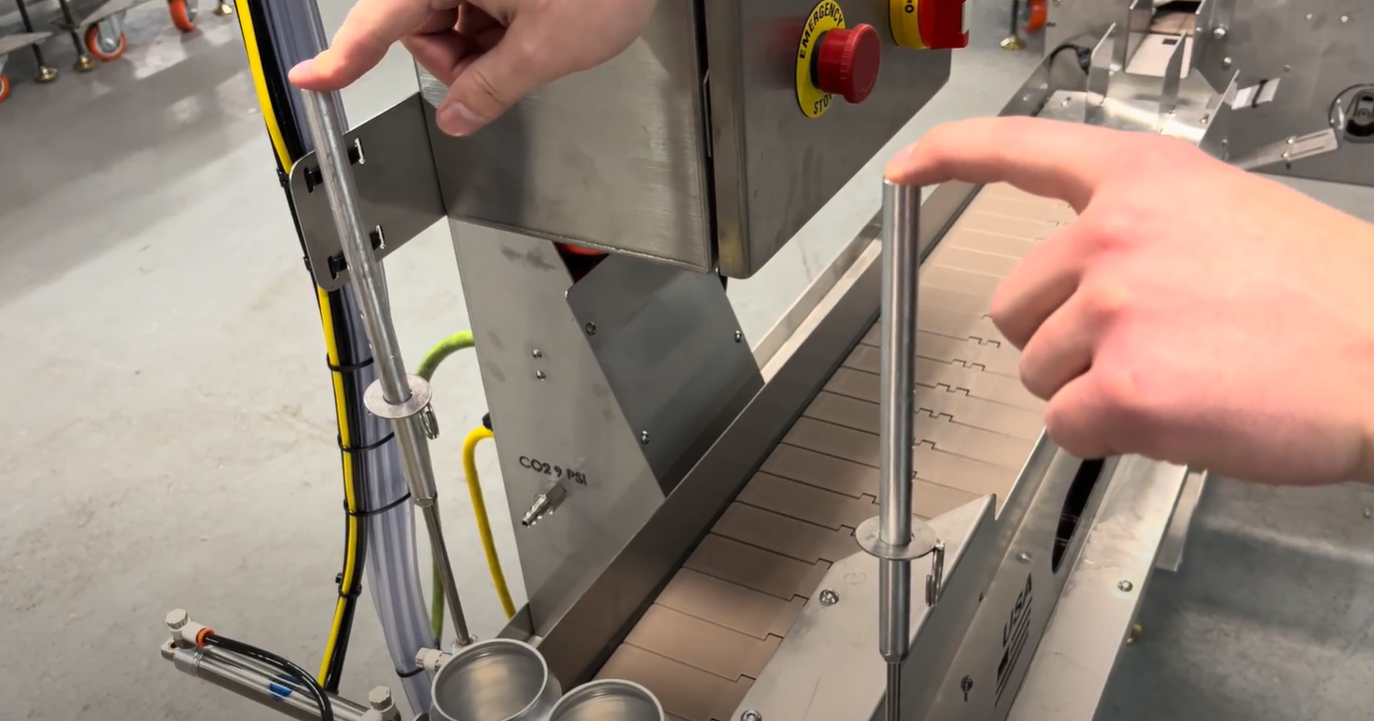

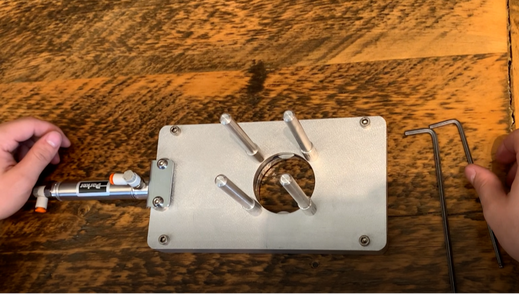

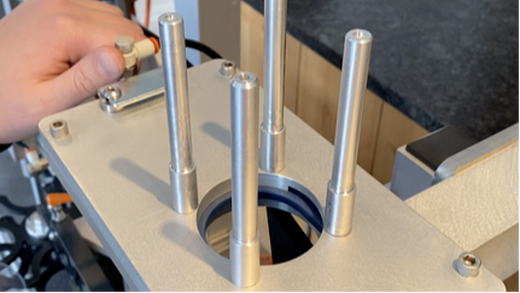

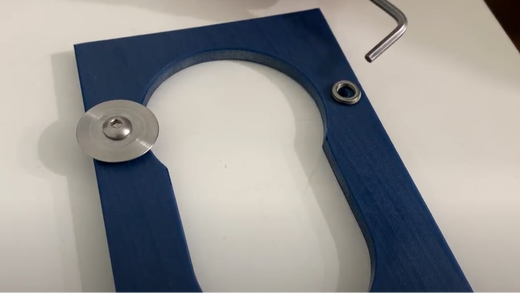

Infeed Sleek Can Change-Over

Teaches how to convert your MC-SWIFT infeed to run sleek cans

Adjusting Swift Filler head speed

Fixes the filler head jamming while travelling up or down

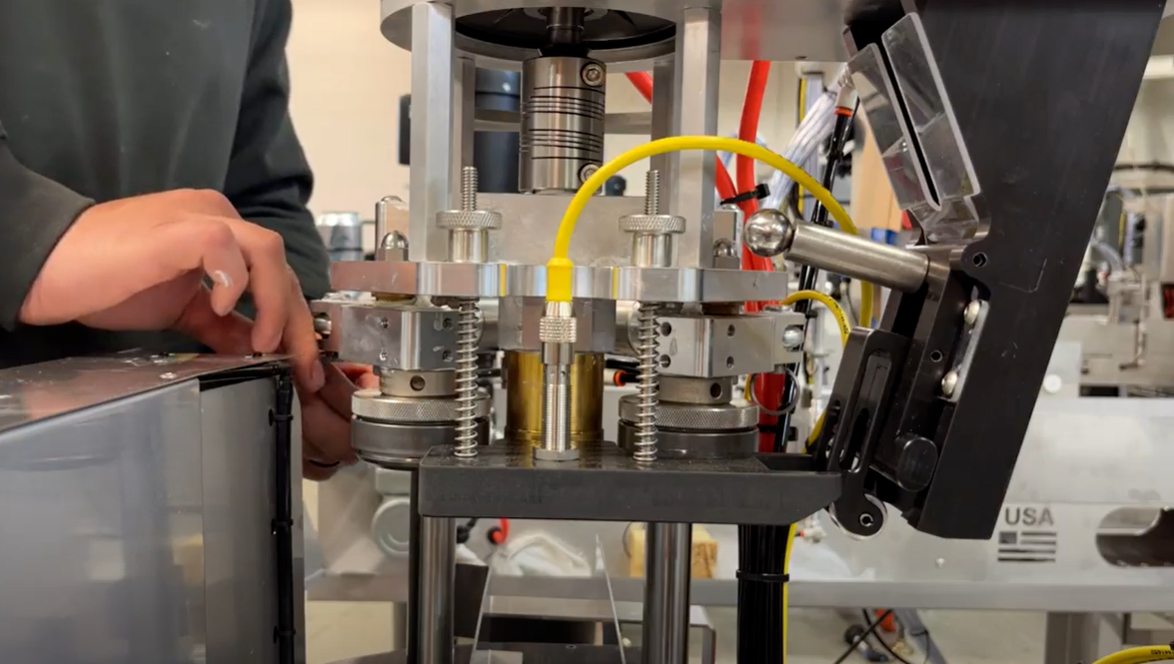

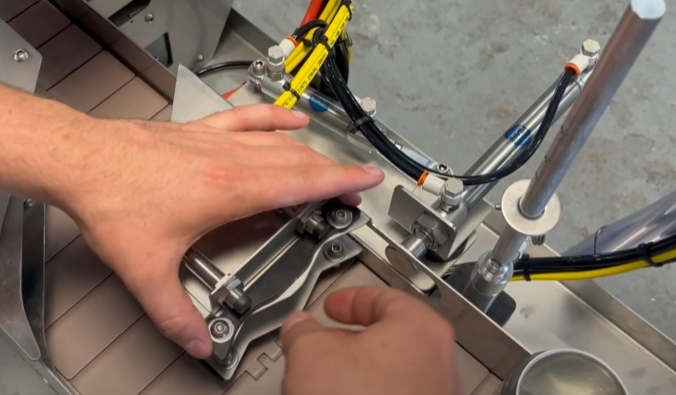

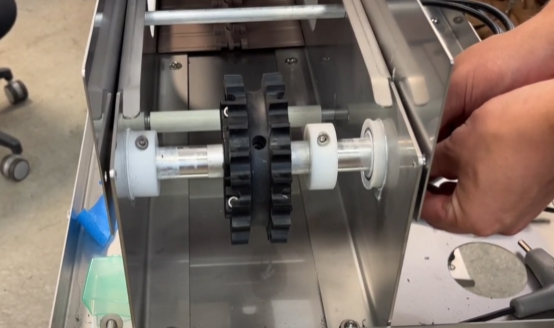

Replacing the Seamer Index

Fixes inconsistent or jolting when indexing the cans into the seamer

Replacing the Filler Index

Fixes inconsistent or jolting when indexing the cans out of the filler

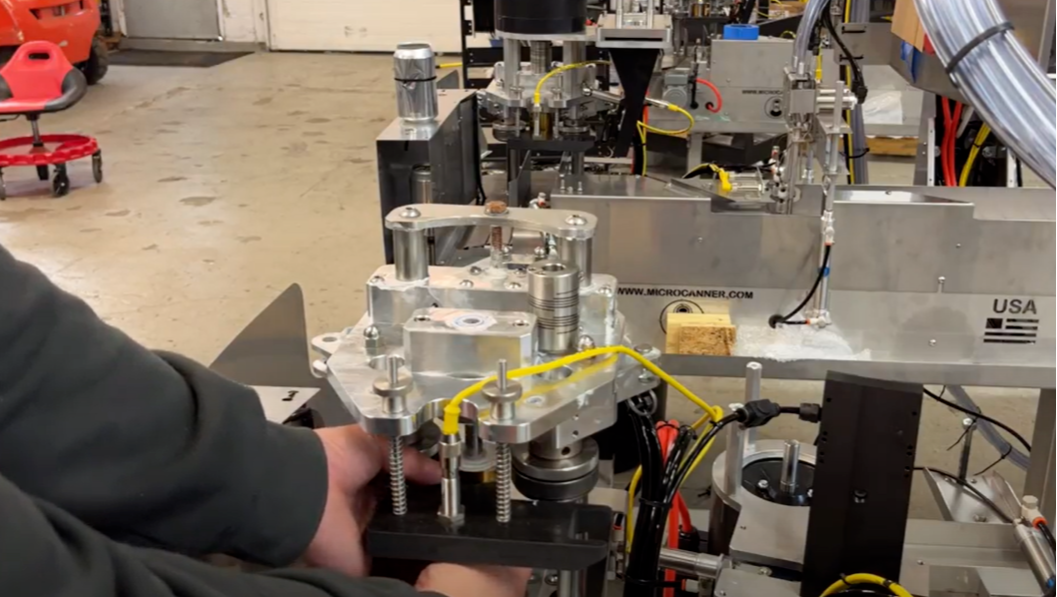

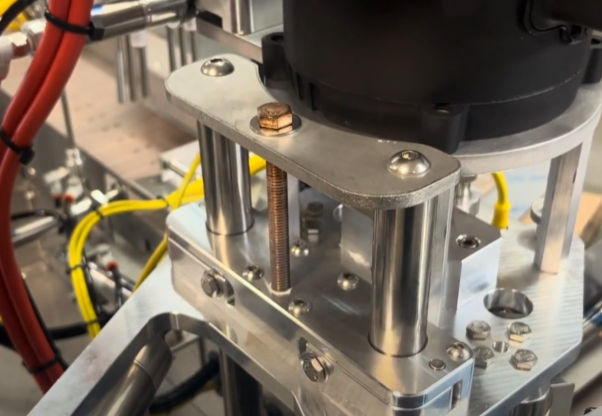

Replacing the Motor Coupler

Teaches you how to replace the seamer motor. This fixes a motor that has power but does not spin even with the chuck hardware disconnected

Replacing Seamer Bearings

Fixes a loud seamer that maybe also producing inconsistent seams

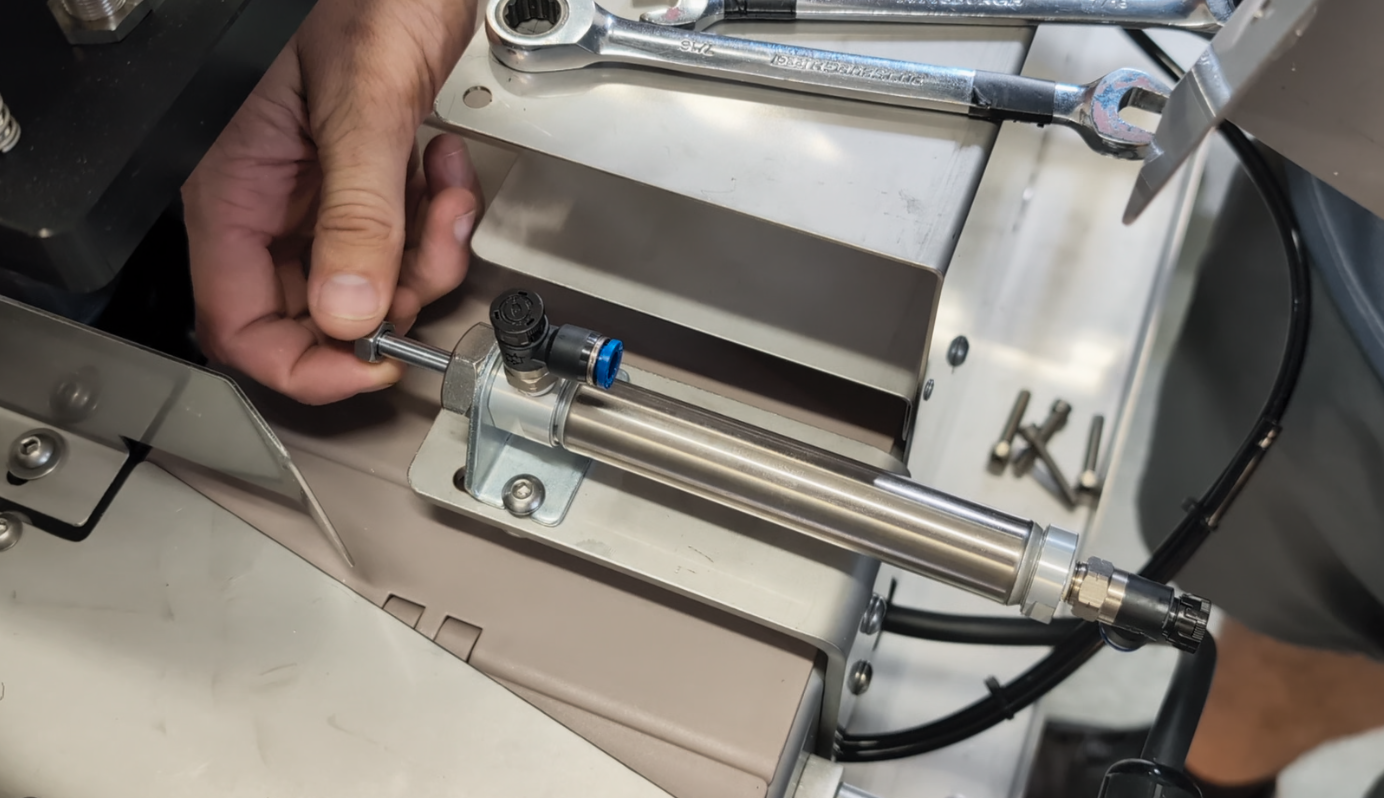

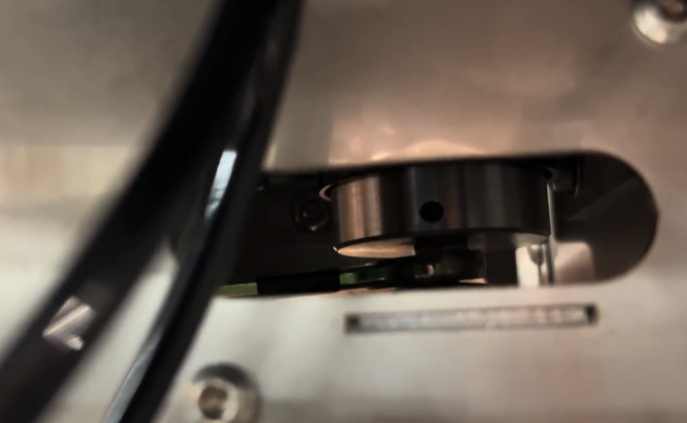

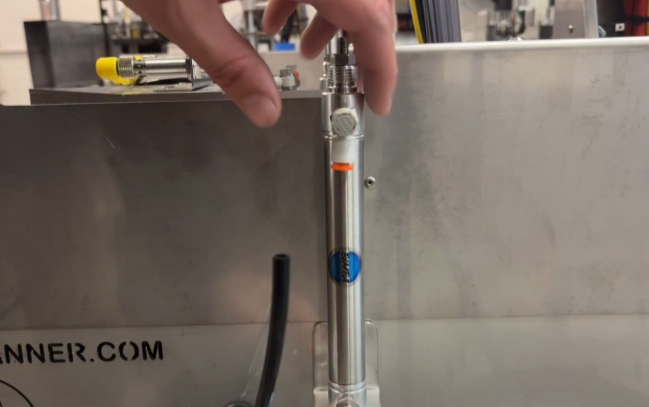

Replacing the Lift Puck Cylinder

Fixes a leaking lift puck cylinder that may be raising or lowering to slowly

Setting the Cap Shedder Speed

Can fix a cap shedder that is shedding two lids when only one should be shed

Adjusting for 88 Gauge Lids

Confirm you have 88 gauge lids before preforming the actions in this video. If you do have 88 gauge lids this will fix jamming and lids not shedding.

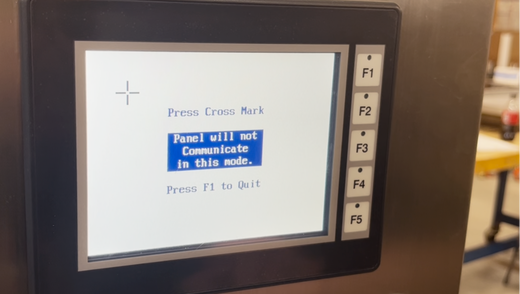

Calibrate Your Touchscreen

Fixes an inaccurate touch screen that is not picking up touch inputs accurately

Filler ready Sensor replacement

Ensure you set the filler speeds correctly after replacing this cylinder!

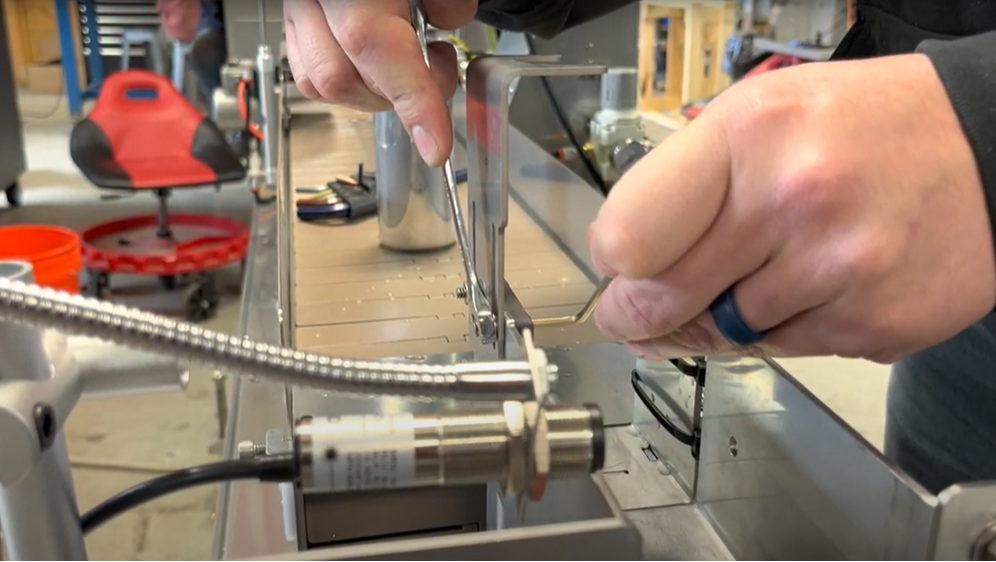

Cap In Place Sensor Adjustment

Fixes a cap in place sensor that's not sensing can lids or that is sensing when no lid is present.

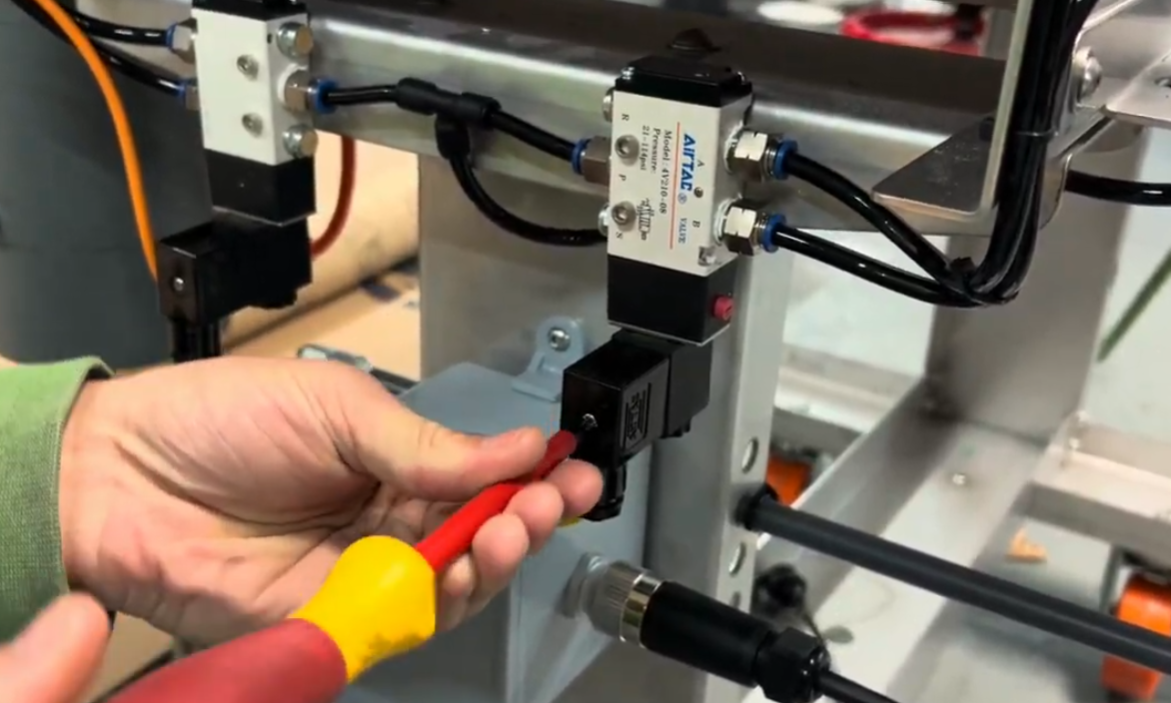

Diagnosing the Infeed Inverter not flipping

This goes over testing if power is making it to the pneumatic valve.